Preventive and Predictive programs are very different maintenance strategies and choosing between them significantly impacts unplanned outages, asset lifecycles, and an organization’s bottom line. Understanding and leveraging these strategies helps you achieve your goals in the most advantageous way.

Preventive maintenance goes by the book or calendar

Any strategy will have its pros and cons. A PM program is no different. On the one hand, you’re establishing schedules and maintaining assets at regular intervals. You’re working to avert failures due to, for instance, a bearing failure caused by missing critical lubrication. Preventive maintenance ensures the bearing stays oiled.

On the other hand, you may be performing unnecessary maintenance. For instance, even though a part is scheduled for replacement, it might be in excellent working order and not truly need replacing for another few months.

In addition to performing unnecessary maintenance, you’ll also incur labor and parts costs. Furthermore, a PM program involves shutting down an asset, which can adversely impact production output. Despite the negatives, keep in mind that statistics show that performing preventive maintenance is less costly than reactive maintenance. PM not only minimizes unplanned downtime but also saves energy by ensuring assets run efficiently.

Predictive maintenance counts on data

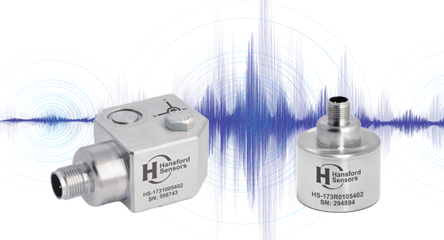

Like preventive maintenance, predictive maintenance (PdM) is also designed to catch potential asset issues before they cause a failure. However, rather than performing maintenance tasks based solely on scheduled intervals, PdM is based on real-time and historical data and performance. Teams using a predictive maintenance strategy consider all vital indicators—such as changes in vibration, temperature and other measurements—before taking action on impending errors. They leverage all the life within assets and components, completing maintenance at the right time and not a moment sooner or later.

Predictive strategies allow teams to decrease impact to production, reduce unnecessary maintenance, and more wisely use resources—all of which improves a company’s bottom line. Reining in costs and streamlining maintenance activities from a calendar to a condition-based program transforms maintenance and reliability into a business value driver.