Webinars

Industrial Standards and Rotating Equipment Purchase Orders

This webinar focuses on the importance of including industrial standards in rotating equipment RFQs and POs.

- Abdullah Balhaddad

- AB Vibration Consultant

Beyond Maintenance Types

In today's rapidly evolving maintenance field, it’s easy to get swept up in conflicting opinions and diverse practices, especially when discussions around maintenance basics and standards are trending online. This webinar addresses common misconceptions in maintenance definitions, classifications, and approaches, which often lead to confusion, inefficiencies, and ineffective maintenance strategies.

- Ahmed Kotb

- Self-employed

Engaging New People to Maintenance

In this webinar, we discuss tips and tricks to getting people's attention to the world of maintenance.

- Joel Levitt

- Springfield

Being a Champion – How to Build an Internal Coalition to Drive Change

We will review key methods to become an internal champion, work with vendors, and deliver results that improve your operation for your team and leadership. Review actual situations of building a business case, finding the right team, and delivering a win for all parties.

- Adam Napolitano

- Triple Circle Partners

Success Management Approach in Providing Predictive Maintenance Services – A Practical Guide

Insightful webinar where we explore cutting-edge strategies for effective asset management especially in the non-heavy industry companies. This session will cover the role of skilled diagnostic teams, challenges and solutions for non-heavy industry companies and the benefits of the subscription-based consultancy model.

- Łukasz Sznajder

- Grundfos

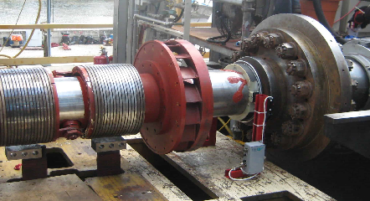

Watching the Invisible – Rotor Torsional Vibration Measurements Using Vorso Transducers

The presentation covers the physical principles behind the operation of the eddy current transducer system, outlines the steps for successful implementation of measurements on industrial machines and provides an overview of sample project results.

- Piotr Mialkowski

- Baker Hughes

Watching the Invisible – Rotor Torsional Vibration Measurements Using Vorso Transducers

The presentation covers the physical principles behind the operation of the eddy current transducer system, outlines the steps for successful implementation of measurements on industrial machines and provides an overview of sample project results.

- Piotr Mialkowski

- Baker Hughes

Leveraging AI & Analytical Efficiency for Predictive Maintenance

In today's rapidly evolving digital landscape, organizations across various sectors find themselves inundated with enormous volumes of data. This presents both a challenge and an opportunity. Successfully navigating this sea of information requires not just traditional analytical methods, but the integration of more advanced computational techniques to drive efficiency and innovation.

- Jeremy Frank

- KCF Technologies

The Reliability No One Talks About

Most of the time, we are able to define and explain reliability engineering to others. It is also possible that reliability practitioners may discuss job cards, oil analysis, vibration analysis, ultrasound, root cause, oil analysis, vibration analysis, and motor current analysis in addition to other topics. If we are so knowledgeable, why do most implementations of it fail at least 50% of the time?

- Benjamin Masinge

- ZAG Mining and Construction

- 1

- 2

- 3

- …

- 14