Preventive Maintenance, or PM, has been around since we’ve had machines, and is typically calendar based, and less often, run-time based. We’ve known for some 75 years that some 90%+ of time-based intrusive PM is not just unnecessary, but actually detrimental to equipment performance and maintenance costs.

Unfortunately, many, or even most, PMs are not well thought out or implemented. Several studies indicate that some 10-30% of a given set of PMs are “spot on”, meaning the other 70-90% need to be modified, or even deleted.

We’ll be discussing these and more issues. Some fundamental questions that should be asked when developing PMs are:

- Are we using RCM principles/data to understand failure modes, and consequences?

- What PM will help us manage these?

- What defects are we trying to detect, or prevent?

- At what frequency do we need to be doing PM?

- Do OEM PM recommendations need to be strictly followed?

- Do our PMs have adequate detail or specificity to tell us when a defect is present, or absent. Check motor is not a PM, it’s a hope.

- Should operators be involved in doing PM?

- Is our CMMS/Work Management system adequately integrated to our PM program to assure its proper management?

- Are our people adequately trained/skilled to perform the PMs, including safety considerations?

- Do we have adequate measures for our PMs, ones that facilitate learning and improvement?

- Do we review our PM program periodically to improve or optimize our practices?

Preventive Maintenance (PM) is time based and is most effective on components/parts that have wear-based failure modes such as corrosion, erosion, and abrasion. In the most effective PM’s known as Quantitative PM’s, the wear is measurable, and one can set a go/no-go standard for when the item should be replaced. While the quantitative PM is most desirable, there are items where a Qualitative PM can be both applicable and effective at reducing the conditional probability of failure. Qualitative PM’s should be very specific in regard to what the person performing the task should look for (panel door gasket is cracked or has become hard) and what should done if this is present (replace the door gasket if it is cracked or has become hard)

Examples of a Quantitative PM

- Measuring chain stretch on a roller chain

- Measuring brake pad wear

Quantitative PM’s should always require the person performing the task to record how much the item has worn.

Examples of Qualitative PM’s

- Inspecting the tires on your car for wear by looking at the wear bars between the treads

- Inspecting electrical panel door gaskets for evidence of leakage, cracking, or hardening

The interval of a PM task should be based on the useful life of the component/part and while that sounds simple enough, several things should be taken into consideration when making this assessment.

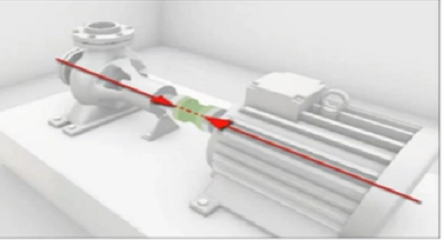

- Was the component properly installed? Alignment, balance, and torque each can have a direct impact on the live of a component.

- Is the item being operated at a consistent rate? Do we use it every day for the same amount of time and at the same speed?

- Have we measure the wear rate?

- What is the cost of performing the PM versus running the item to failure?

- Have we use the correct materials for the environment it is operating in?

Beware of using statistical tools for determining PM intervals until one is absolutely clear in regard to the above questions. My advice to companies is to take a conservative guess to begin with and adjust intervals based on YOUR data!

Operator PM’s

Today’s manufacturing plant seems to like to call Operator PM’s something other than what they are. As a result we have TPM tasks and Operator Care Tasks, but in truth they are simply PM tasks performed by the operator. The same rules apply for Operator PM tasks. We will have both quantitative and qualitative operator PM’s.

We hope you enjoy this episode!