This is the last of a three-part series on Understanding the P-F Curve. The last article will be a brief review of the two earlier articles and ending with a focus on an article and presentation published by Dustin M Etchison, CMRP with Elanco Global Engineering that brings all the aspects of equipment reliability and safety together. Mr. Etchison has been so kind to allow us to use his article titled “The Impact of Equipment Reliability on Human Safety” to make the point that there is a direct correlation between reliability and safety at the Young Station.

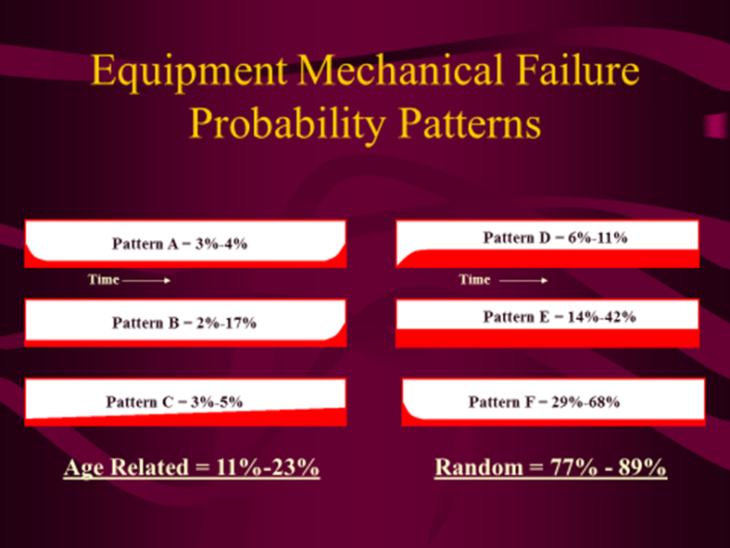

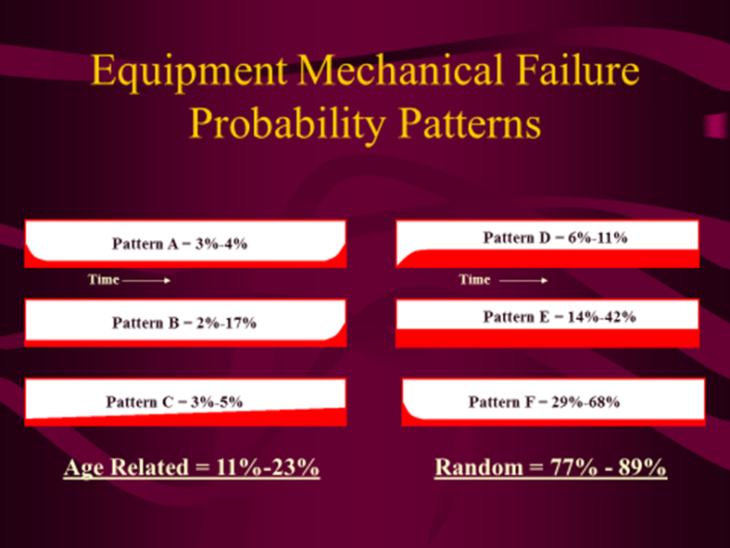

In the first article, explained that over the course of time equipment failures will occur. Studies performed by United Airlines, the US Navy, Bromberg and RCM by Nowlan and Heap have provided evidence that there are different patterns relating to failures and time intervals. A majority of failures in industry have been determined to be randomly (specifically infant mortality pattern F) and not age related.

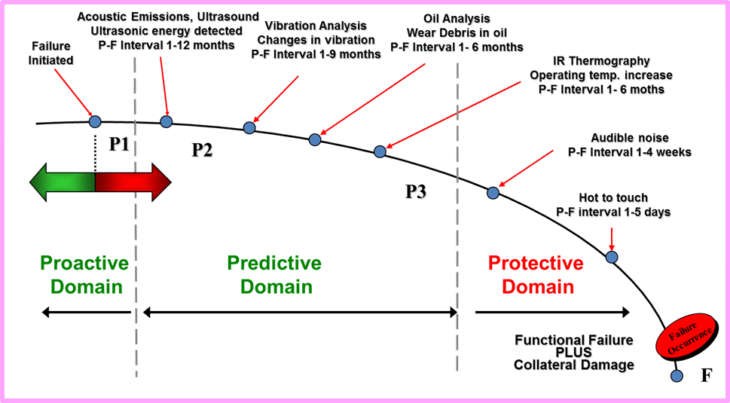

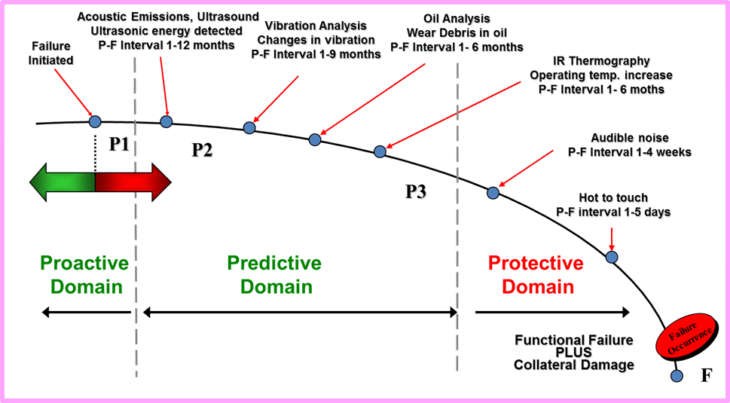

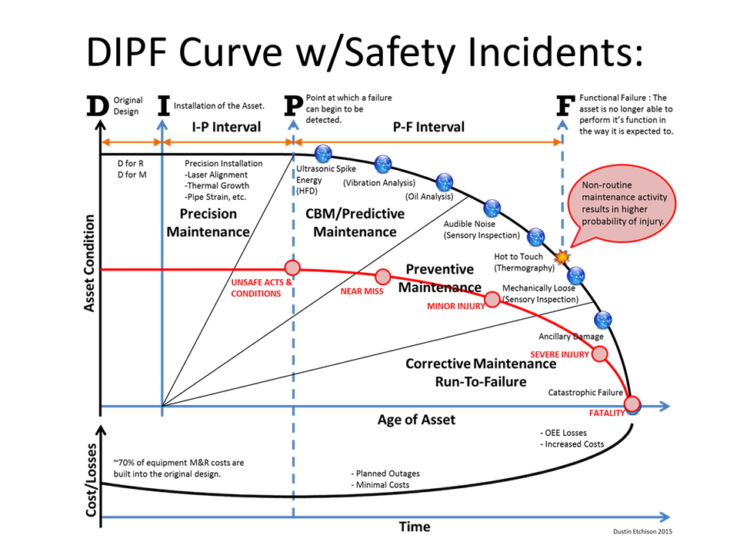

In the same article, we demonstrated that the understanding of how these failures occur could help establish the methods for early detection using condition monitoring. This early detection of a failure mode is helpful in applying the appropriate priority to corrective repair work orders, allows for planning and scheduling of resources to make repairs before a catastrophic failure occurs.

The type of condition monitoring technology used to detect the problem and the level of energy the problem is emitting – along with the P-F Curve Interval – is helpful in applying the appropriate priority to corrective repair work orders.

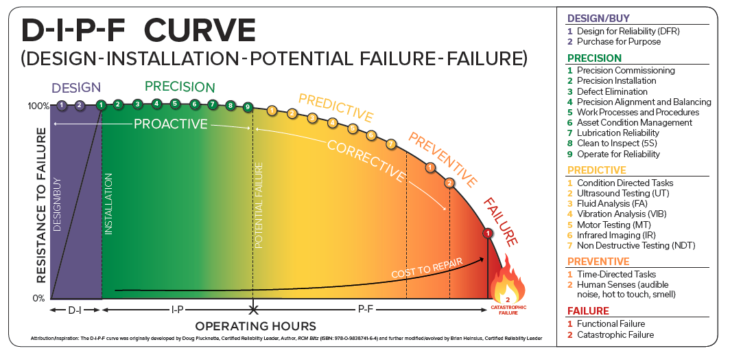

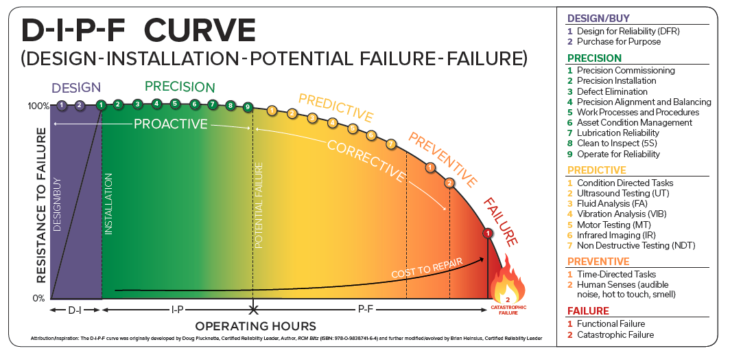

The second article describes two programs that are capable of reducing and/or eliminating the random failures patterns and thus extending the proactive domain timeline on the D-I-P-F curve (D-I-P-F Curve developed by Doug Plucknett CRL, modified by Brian Heinsius CRL and permission to reprint provided by the Relaibilityweb). This increase in reliability and the value it creates is a huge advantage in helping an organization sustain its competitive edge. These benefits can be recognized by implementing a comprehensive reliability, precision maintenance and precision operations program. Items within these programs include:

- Life Cycle Asset Management Plan

- Design for Precision/Reliability

- Procure Quality

- Precision Assembly, Alignment and Balancing

- Precision Installation

- Precision Commissioning

- Operator Care

- Work Processes, Procedures and Standards

- Asset Condition Management

- Lubrication Reliability

- Clean and Inspect (5S)

- Operate for Reliability

The Impact of Equipment Reliability on Human Safety

Dustin M Etchison, CMRP

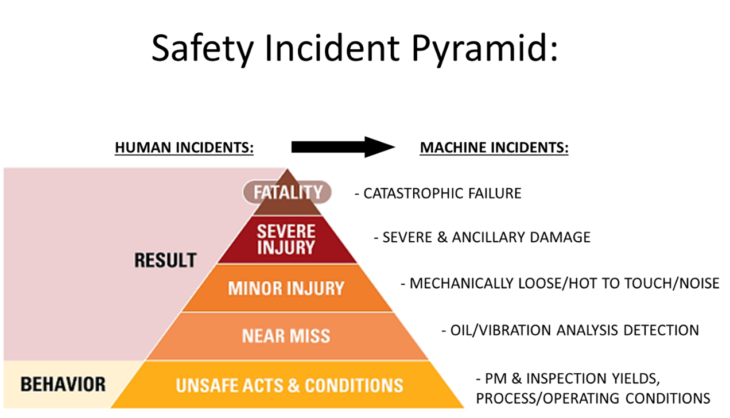

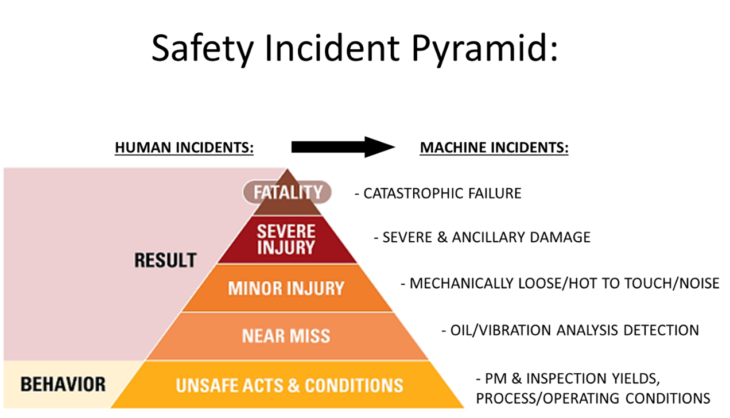

To understand the connection between reliability and safety, we need to look at the Heinrich Safety Triangle. The safety incident pyramid is a broad focus on human safety in an industrial organization.

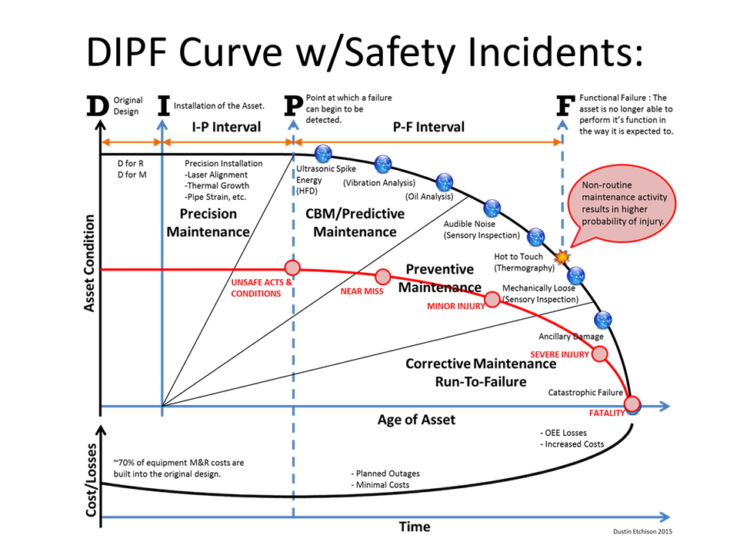

There is a direct correlation in the importance of human safety to the importance of equipment reliability. The understanding of both are critical in driving an injury-free culture. Keep in mind that the probability of an injury is significantly increased with non-routine maintenance activities resulting from equipment failures (reference the DIPF Curve with Safety Incidents).

Human factors such as rushing, frustration, fatigue, and complacency have an impact on both human safety and equipment reliability. These factors lead to unintentional, risk-increasing errors like eyes and mind not on task, being in or moving into the line-of-fire, or losing your balance, traction, or grip. Similar to human safety, these factors can result in precision maintenance gaps like incomplete or improper precision alignment, PMs, or gaps in other maintenance related tasks.

Effectively managing these human factors will net positive results in both human safety and equipment reliability.

Please note this article reflects the views, thoughts, and opinions of the author only. The author has been working in the fields of condition monitoring, precision maintenance, and reliability since 1983.

why the envelope lines are diagonal not vertical