As artificial intelligence permeates more-and-more into manufacturing plants, the “multi-disciplinarian” will emerge as the new, “got to have”.

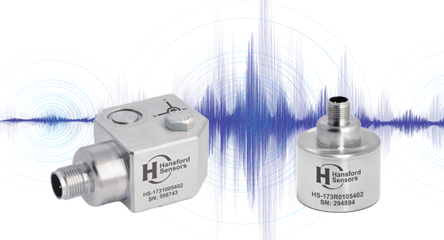

Reliability professionals face a great challenge as well as an exciting opportunity. With the tsunami of high resolution, low-cost sensors that have come onto the market, along with machine learning and cloud computing, the multi-disciplinarian will take his/her place. Until now, reliability professionals were generally schooled and skilled in one discipline. Experts in vibration, oil analysis, infrared, motor currents and the list goes on-and-on.

While this has served the industry well, with the advent of artificial intelligence, change will happen. AI has enormous capability to combine signals from a multitude of data sources to perform multi-variate analysis in seconds where a mere mortal would take days or weeks to filter through the data to try to make a decision. This decision will not come close to the accuracy that a computer is capable of in the world of plant operations.

Instead of looking at silos of data, citizen data scientist tools are emerging to allow the engineer to combine signals that grow over time and become early warning signs of potentially catastrophic failure. This new human/computer interaction will be the norm for a new kind of reliability engineer. This is an engineer who is comfortable in using tools to harness vast amounts of data coming off sensors to predict the future and prescribe the corrective actions required based upon both current and future state that can now be forecasted with great accuracy. Lately I see examples every day where expanding the horizon to look at larger set of data with new tools would have mitigated serious damages later.

Take the case of a large off gas multi-stage reciprocating compressor at an oilfield that had to be stopped due to high vibrations. Stoppage inspection immediately revealed failure of the second stage discharge valve causing leakage. Closer monitoring of day-to-day variations of valve temperatures and thermodynamic efficiencies would have detected the issue in advance and thereby avoid the unplanned stoppage.

Another example, we recently saw in excessive scaling of a large centrifugal blower at a petrochemical plant. The scaling in the impeller blades was near-instantaneous, unexplainable, and caused periodic shutdowns due to vibration overshoots. Mechanical fixes were done, but the issue remained. An AI-driven online digital twin of the process revealed interesting patterns around lack of appropriate temperature control in an upstream crystallizer circuit that led to solid entrainment in gas going to the blower.

In both the cases above, it is clear a multi-disciplinary ability to analyze data from multiple sources and methods – process and mechanical – are the need of the hour to get a holistic assessment and timely insights on health that may remain hidden till it becomes too late to avoid damage.

As digital manufacturing becomes the norm, there is no doubt that this new hero will emerge and take center stage in plant operations.