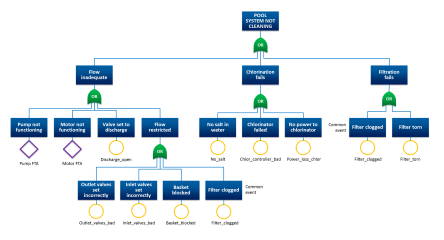

Root Cause Analysis (RCA) is great tool, but only if you know when and how to use it.

Without the right business processes in place – that is, a robust process flow that clearly spells out trigger points, roles, responsibilities, and accountabilities – then RCA can fall flat. In this second blog of three exploring common pain points when it comes to RCA, we look at the importance of creating standard procedures when it comes to solving problems.

Start with proper documentation

It’s a great idea to invest time and resources upfront to document your RCA process. Your written protocol should include:

- The triggers that lead to an RCA – these need to be carefully considered so you’re not doing too many (or too few) RCAs each month

- The employees responsible for RCA – a team of facilitators, ideally coming from the front line in production or operations

- How quickly it needs to be done – ideal turnaround times for investigations

- Which system to use to complete the RCA – your systems and software

- Who reviews completed RCAs – a trained member of your management team

Once this document is in place, then it doesn’t matter if your current RCA champion leaves the business. The trigger points ensure the process is initiated and anyone can easily reference the documentation to see exactly what needs to be done. But if your RCA champion left tomorrow, and you didn’t have this documentation in place, then you’d likely have a problem, right?

RCA requires ownership

One critical element of successful RCA is accountability. That is, giving clear ownership of the process to a person or team with clearly defined responsibilities. You can do this by making sure it is part of that person/team’s KPI’s, so that performance can be measured against the success of any RCAs that occur.

It’s a good idea to create a critical mass of people who understand the RCA process. To do this, you need to build an ongoing, cyclical training and support program, with regular health checks, that starts by identifying and training an initial group of employees who would make great facilitators. Ongoing support reinforces the learning and one year in, these facilitators would need refresher training – at which point you could identify and bring in a new group of RCA facilitators to train.

This process builds and strengthens your capacity in RCA.

It all comes down to due diligence

There is little value in completing an RCA if it’s simply a ‘check the box’ exercise or if management has the attitude that it’s ‘just something to get done’.

To get to the point where RCA helps you eliminate defects and recurring problems to realize a state of continuous improvement, then you need to ensure that the managers responsible for signing off on the outcomes of an RCA invest proper time and attention in doing so. All managers need to be trained on the intent of your RCA program and need to know who is responsible for ensuring the program’s quality.

We’ve seen RCA reports signed off by management teams even though the reports themselves were missing key information or were completely misleading. Sometimes, the quality of the report is not audited. Other times, mediocrity is accepted. Either way, it shows a disregard for the RCA process – perhaps driven by a lack of faith that RCA can lead to bottom-line results. But, done right, RCA can make a huge difference to the bottom line. The asset that was offline for 100 hours and cost the business $100 million? If an RCA had been done properly last time it failed, then you wouldn’t be saying goodbye to those earnings.

Management teams need to make it clear that they believe in and respect the RCA process. Building a culture of continuous improvement – which, in turn, requires a culture of problem-solving helps to spread a strong message across the entire organization. Change can take time, and it is often met with some resistance, but it is most certainly worth the effort.