There is often confusion or a lack of understanding about the role of a reliability engineer in an organization. Very office they are just a maintenance engineer that’s had a title change, or a condition monitoring engineer with a title change, or something else. Is there confusion surrounding these job roles? In this podcast, we’ll discuss the roles and responsibilities of a reliability manager and/or engineer. Depending on the organization, the following responsibilities may be included:

1. Measure, prioritize, and analyze production losses from ideal. Develop plans to address these.

2. Facilitate cross-functional teams in addressing these losses to build collaboration into the culture of the organization.

3. Develop and staff, including contractors, a condition monitoring (CM) program based on failure modes, consequences and criticality.

4. Review and modify the PM program to assure PMs address failure modes and consequences and have adequate specificity.

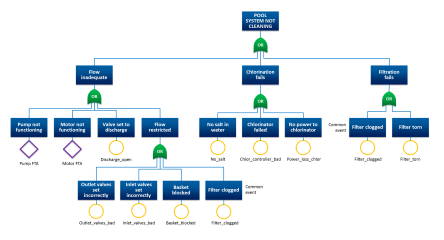

5. Lead, or manage an RCA program, including follow up actions.

6. Provide shutdown support based on the CM and PM program results. Provide startup support to verify work quality.

7. Identify training needs for supporting reliability, including training for operators and maintainers.

8. Interface with repair shops, including contractors, to assure the right standards and specifications are in place, and followed.

9. Interface with maintenance, production, stores and others to facilitate collaboration in defect elimination and provide guidance regarding key practices.

10. Report to the Site Manager, not the Maintenance Manager – Reliability requires the alignment of production, maintenance, procurement, and engineering managers to be effective.

Clearly this is a heavy load and will require tailoring to suit any specific site. We will discuss these elements, providing ideas for consideration and action.