The Performance Centered Asset Management concept is designed to optimise the inherent value of the assets in terms of Safety, Environment and Business: Global Sustainability. The concept provides simple tools and methods to bridge the gap between

– workers and management,

– operation and maintenance,

– maintenance and engineering.

It also provides a pragmatic process to connect the information systems (e.g. CMMS / EAM) with the actual asset analysis (e.g. RCM analyzes). It is based on international standards. The whole point is to get the most value out of your physical assets; People, Planet and Profit.

The P-CAM process uses a holistic approach based on adaptability, ease of use and efficiency.

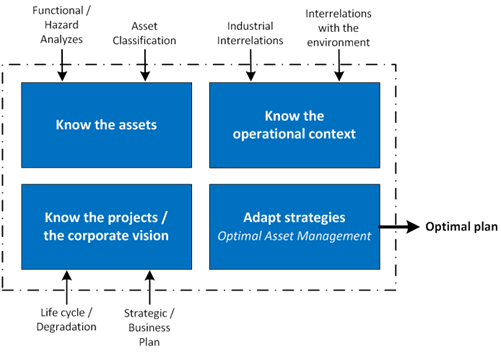

Asset management starts with knowledge about the assets, not only of their purposes, but especially of their associated hazards and vulnerabilities.

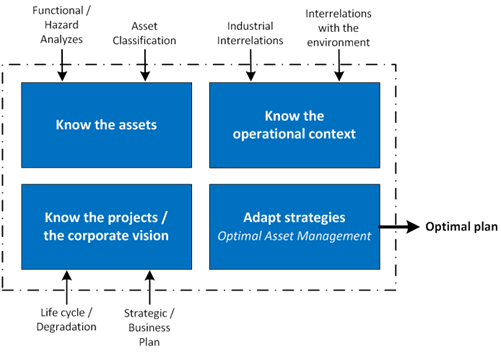

Figure 5: Understand Prioritize Optimize

Now, which asset to begin with? Too often, we tend to focus on the production lines, while other systems might put the company at greater risk.

For example, in the hydro power production, one can focus on the generators, concern by the operational consequences, while a dam breakage or a spillway malfunction would put the population at risk.

A less catastrophic example in the manufacturing process, one tends to focus on the machining centers, while a failure of the main chip conveyor or the main compressed air system would stop the whole factory. What about the main power supply, have you ever lost it?

In general, common ancillary equipment represents greater vulnerabilities to the company than the main production assets, on which one tends to focus the efforts. So, in order to properly assess the company’s vulnerabilities, all of its assets must be analyzed and classified accordingly. To accomplish this in full detail for each asset would require an unreasonable amount of effort. Using the P-CAM process tools, it is possible to classify more than 600 assets (an entire factory or a complete site) in a 2 day’s workshop, with the right team and a proper common understanding of the basic concepts. Then, start working where it matters the most.

Another advantage of the P-CAM Process is the process itself and its retroactive characteristics. Too often the analyzes do not get to be reviewed. They die on the shelf, with people too busy by their everyday routines to update them.

The P-CAM process is part of everyday life. It takes root in routines and its concepts are integrated into the tools. It influences the culture of the company, pulling everyone on-board.

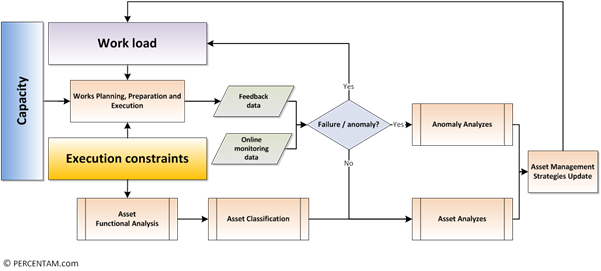

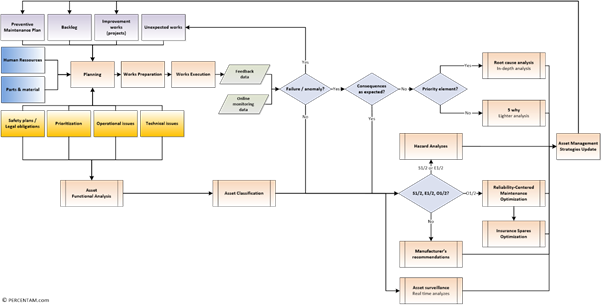

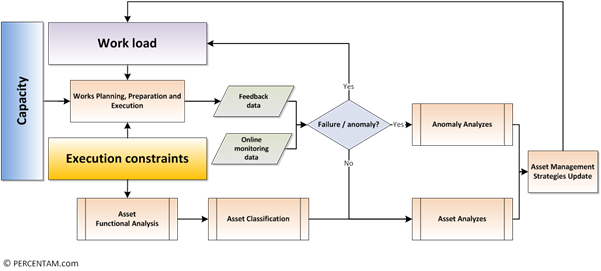

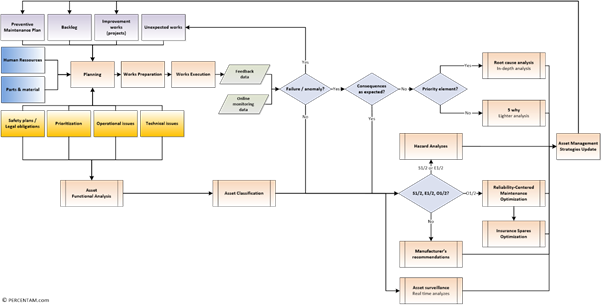

The process presented in Figure 1 shows the basics of the P-CAM.

Figure 1: P-CAM process – simple view

This retroactive process is part of a continuous improvement culture. You can start looking at it from the “Work Planning, Preparation and Execution” step. This step is fed by the “Workload”, the “Capacity” and the “Execution constraints”.

Then, the data collected in the “Feedback reports” and the “Online monitoring data” are subject to a first filter used for early detection of anomalies. These last ones increase the load with unexpected work and are subjected to “Anomaly Analyzes”. This is sometime known as the “Defect Elimination” sub-process. When no anomalies are detected, then the data feeds into the normal analysis steps.

When developing a process, always be mindful of the details: Do not go into it. Have you ever heard the expression “Stuck in details”? Remember that almost 90% of initiatives fail because of far too many details. For example, with the “Asset Classification” step, do not use several indicators with a 1 to 10 scale each. First, you will not deliver the analysis because the team consensus on the numbers will be unreachable. Second, if you do reach something, you could be tempted to do some mathematics with the numbers in order to prioritize and from there, make biased decisions. Why biased? Simply because these indicators are nothing but qualitative. Mathematics require quantitative indicators, not qualitative. The P-CAM Asset Classification Tool uses a go/no-go approach which quickly delivers useful results.

The first thing to get done is to understand what you are to achieve, as a group, a TEAM. Have a common understanding of the basic concepts. Line up the vocabulary, then start assembling the rough parts. Do not worry about the details, as they will naturally arrive in due course as primary data feeds and leads the way – Data Driven Processes.

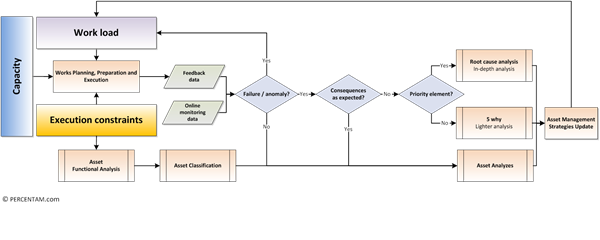

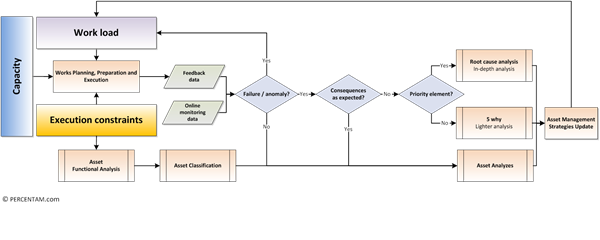

Figure 2: P-CAM process – intermediate view

This view of the P-CAM process expands the “Anomaly analyzes“ step.

Some anomalies are expected, like for a “run to fail” strategy. The only attention such anomalies require is to ensure the consequences are as expected. While other anomalies require full attention and dedication, like a safety failure, an environmental accident or a major operational blockage. In between, stand the anomalies with unexpected consequences that need to be addressed with the appropriate amount of resources to be efficient and really perform in terms of asset management. To perform, only use the required amount of effort, not more, not less.

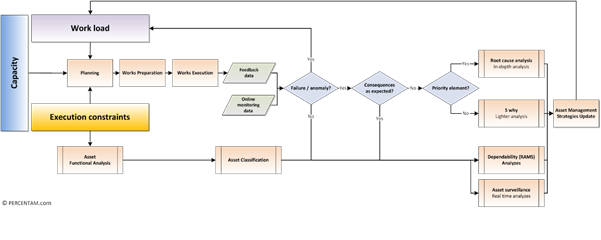

Figure 3: P-CAM process – intermediate view

This view of the P-CAM process expands the “Work planning, Preparation and Execution” step.

While chaos might feel good to certain people, it is always costly. So, to prevent drowning into disorganized work, where everything is more urgent than the top priority, you need to plan, prepare and execute work accordingly.

The view also expands the “Asset Analyzes” step.

This part is about valuing the data. How many of you are gathering real time data, without using it? There is no point suffering a failure to realize that you could have seen it coming weeks ahead, sometimes months.

Unused data is costly, very costly. It is of great value, when used to predict, plan, prepare and execute work just on time to prevent failures. It also is very useful to help discriminate between the major projects requirements (Capital Expenditure), and develop the mid to long term investing strategies.

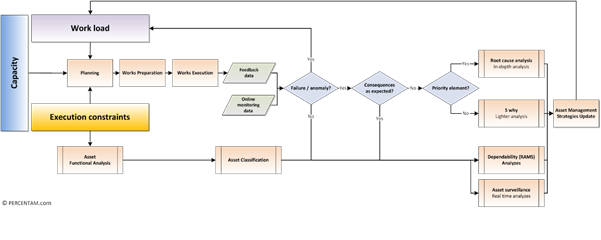

Figure 4: P-CAM process – detailed view

This final view of the P-CAM process expands the “Work load”, the “Execution constraints” and the “Capacity”.

Performance can only be achieved when these three elements are balanced. So, they need to be defined, commonly understood and managed properly. They also need to be updated, following the business evolution.

The view also expands the “Dependabilty (RAMS) Analyzes” step.

To perform, know your assets. Not only the obvious production lines, but all of it, including buildings, ancillary equipment, civil infrastructures, roads, lands, mobile equipment, emergency systems, stand-by equipment and disaffected assets.

Make sure, as a TEAM, to clearly understand not only their purposes, but also their associated hazards and their vulnerabilities. So, the right decisions can be made to ensure the successful and safe operation of your business.

All of this knowledge is used to update the Performance-Centered Asset Management strategies.

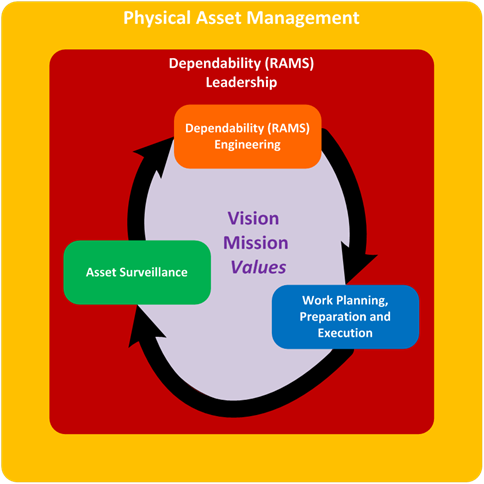

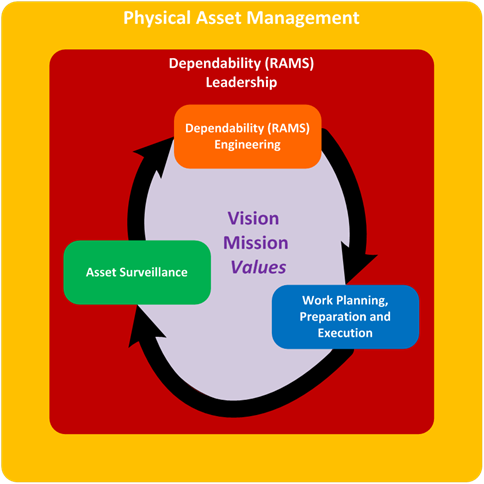

Figure 6: Integrated approach

In conclusion, innovation is about mastering and adapting established concepts, rather than inventing them again. The challenge is to integrate them into a concise process, delivering strategies aligned with corporate goals and tailored to the local operating context.

These existing concepts have been gathered into a holistic approach, the P-CAM process. Its purpose is to deliver results without burden or endless analysis. To achieve this, you need to get everyone on-board, so the approach has to be simple, robust and engaging. Its originality lays into its simplicity.

In summary, the P-CAM process consists of:

– naming, locating and classifying assets,

– planning, preparing and executing works,

– documenting the interventions associated with it,

– surveilling and monitoring the assets,

– analyzing the data recorded, and from there,

– updating methods and optimizing asset management strategies.

The P-CAM process is based on international concepts in asset management, including prioritization, dependability and industrial maintenance types. It considers the local specificities, regarding operational, technical and asset configuration constraints. The Performance-Centered Asset Management analyses are synchronized with information systems (e.g. CMMS / EAM) by:

– an inventory structure / equipment register based on the functional analysis,

– standardized nomenclatures, codes and associated vocabulary,

– the association of failure reports directly to components using generic codes for optimized statistical analyses and direct failure vs asset management strategies feedback.

Your people are the essence of a successful asset management process. Bring them together with small daily successes, improve little by little every day. Get them involved, engage them and from there, together, you will be able to do anything.

Let’s build together a sustainable future.

Visit percentam.com for more info.

Pascal CLEMENT, CRE, CRL, CMRP