Lubrication is the ‘poor relation’ of many maintenance programmes, often insufficiently understood, badly stored and haphazardly applied. But, when planned and implemented correctly, a lubrication plan will not only improve efficiency and save money, but also make significant improvements in terms of energy conservation, waste management and staff safety. As such it should be one of the bedrocks of any condition monitoring (CM) programme, says Mark Needham of AVT Reliability®.

What manufacturer would turn down the opportunity to resolve almost three quarters of problems commonly associated with engineering equipment breakdown?

The answer to this of course should be none. But the fact is that a very real opportunity to do just that is being overlooked by any company which does not have an efficient lubrication programme embedded in its maintenance plan.

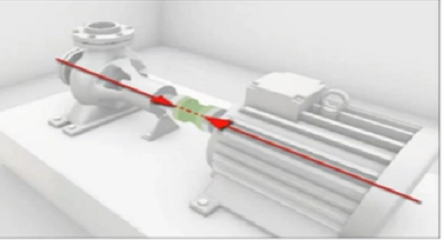

It is generally accepted that poor lubrication practices account for around 70% of equipment failures. There are multiple ways in which to get it wrong, but typically these will include using the wrong type or amount of grease or oil, using contaminated lubricant, applying it badly, storing it badly – or any combination of these.

The damage, friction, overheating and wear this leads to accounts for a significant proportion of bearing and gear failures and other mechanical complications that demand time and money to remedy. The potential for unnecessary additional cost should not be underestimated.

One petrochemical company had a small bearing fail as a result of inadequate lubrication. The cost to replace the bearing was £150 but the overall could have cost the company in excess of £250,000 because the failure occurred on a conveyor belt at the highest point of the production process, with the potential for the damaged / failed components to drop down into the machine, halting production.

Similarly, a chocolate manufacturer was fortunate to narrowly escape the cost of halted operations (for a minimum of 24 hours), wasted product, subsequent dig-out of the hardened process and clean-up costs – purely because a failing £100 bearing was spotted whilst carrying out a visual inspection during the lubricating activity, and before the machine stopped running and caused system back-up.

These may seem like extreme examples but if you were to calculate just the accumulated cost of every unscheduled bearing or gear replacement over the course of a year, the total would probably surprise you.

This operational and financial risk could be significantly reduced simply by putting in place a well-planned and thoroughly implemented lubrication programme. In addition to your assets being more efficient and reliable, you would also see benefits in terms of energy efficiency, environmental sustainability and workforce safety.

Problems of poor lubrication

Management and operatives alike have a tendency to think that lubrication is a very simple matter, when in fact it is anything but. There is no ‘one type fits all’ lubricant – different operating conditions must be considered.

Yet this attitude means that lubrication is often treated as the poor relation of a maintenance plan when it should be an elder statesman. As a result, responsibility may be offloaded onto an operative with no training or expertise. And if senior personnel don’t place importance on the lubrication programme, why should they?

Reduced reliability, increased costs

A careless approach to lubrication means situations occur where, for example, ‘blue’ grease (regular load) is applied where ‘red’ grease (for higher operating temperatures) is required. The potential issue of miscibility could thin the soap, reduce the viscosity of the oil, and affect its additives, which is then unable to carry the load. Increased friction between metal surfaces creates debris, which damages bearings and gears, leading to reduced reliability and, eventually, equipment failure and costly downtime. The greater the friction, the more energy is required to drive gears, whereas good quality, appropriately applied lubricant removes the drag on equipment, reducing energy consumption.

False economy

A low-cost non-food grade oil might be priced at as little as £50 a pail – an attractive figure to a procurement manager keen to reduce outgoings. But it will, inevitably, be lower quality and will need replacing far more frequently than a higher grade oil, potentially changing a low grade poor quality oil on a yearly basis, compared to a potential 5 yearly change for a superior lubricant. Bumping its cost in real terms up to £250.

Add this additional cost to those incurred through stoppages, repairs and replacements, manpower to carry out this additional work and you have to conclude: cheap oil is expensive.

Environmental benefits

A high-quality lubricant will potentially only require changing once every five years. As well as lowering ongoing purchase costs, you are reducing the amount of waste you produce, which should be of importance to any company working towards ISO 14001.

With an estimated 40% of all lubricants being released into the environment and strict regulation costing some companies in waste water treatment to ensure they meet their legal requirements; the potential savings are also huge.

A safer workforce

Reduce the number of occasions you change the oil on a piece of equipment and you immediately create a safer environment for operatives. The manual handling issues associated with carrying a 20kg pail of oil are obvious. If you need to change the oil just once a month instead of once a week, your risk is significantly diminished purely by reducing the frequency with which you carry out the task. It’s that simple.

Technology for reliability

Advanced technology can take the pressure off operatives and embed lubrication firmly and effectively within a reliability programme.

Web based condition monitoring systems, such as Machine Sentry® will use information gathered through a lubrication audit to schedule when to apply oil, which oil to select and how much to use, as well as enabling you to track oil changes and greasing regimes.

Lubrication data is collated on one platform, along with a range of other data, such as vibration analysis, and can be viewed in isolation or in the context of wider CM activities. Built-in alarm settings issue alerts if lubrication is under or over applied, pre-empting problems which might have arisen down the line and maximising the reliability of equipment.

Any authorized personnel can securely access this cloud-based data from any location, using a standard web browser, so informed decisions can be made swiftly and, where necessary, remotely.