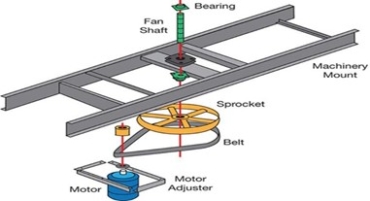

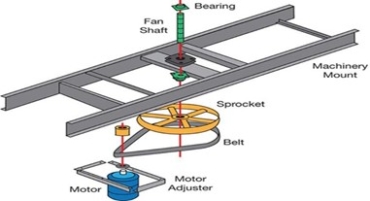

Fin fans coolers are necessary equipment in every oil and gas facility. Fin fans are heat exchangers, usually utilized to cool equipment lube oil or to reduce product temperature. If the fin fans fail, lube oil temperature will increase, which might trip the equipment. In case of failure in cooling the product using fin fans, the downstream equipment could trip due to high suction temperature, or suffer from cavitation in the case of pumps.

Fin fans come in different arrangements. The most common arrangement consists of a fan driven by an electric motor using two pulleys and a belt to transfer the energy. Although it is a basic arrangement, their premature failures could impact the overall cost and equipment availability, especially if there are a large

number of fin fans in the plant. Therefore, proper maintenance is very important, to ensure their availability at optimum maintenance cost. After analyzing the common failures of the belt driven fin fans, there are three major causes of failure: pulley misalignment, improper belt tension, and wearing out.

Figure 1 Fin Fan Arrangement

Figure 1 Fin Fan Arrangement

Pulley misalignment

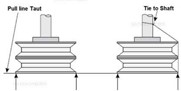

Figure 2 String Line Method

Most belt failures are caused due to pulley misalignment. One of the common practices utilized for pulley alignment is string or straight edge methods to detect pulley misalignment. Moreover, using these methods could lead to inaccurate results. Alignment can be very challenging, especially at high elevations with hot temperatures due to other fin fans.

Figure 3 Laser Alignment Tool

One of the great tools to perform proper pulley alignment is laser alignment, where it can detect three types of misalignment (offset, vertical, and horizontal). To check the performance of this tool, a pulley alignment was conducted using the string line method. Then the laser alignment was installed to compare the results. The laser alignment showed the pulley still had an offset, and more importantly, a horizontal misalignment that could not be detected by the string line method.

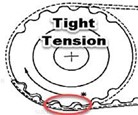

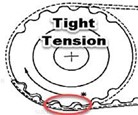

Belt Tension Meter

Belt installation requires proper belt tension. There are a number of factors that determine the correct belt tension, such as the belt’s mass, length, and condition (new or used). A commonly used practice is the quarter of a turn method. Basically, the belt will be turned 90°and based on the belt’s resistance, it will be tightened or loosened. In case of a V-belt, if the belt was very high, it will wear out the pulleys and the belts before its designed life. In case the belt was loose, it will slip and generate more fraction and heat. In case of a timing belt, the teeth will hit the sides of the pulleys and cause damage to both the pulleys and the belts. The quarter of a turn method is inaccurate, as it depends on human strength, which will vary from one person to another. This method could be replaced by using a sonic tension meter, which will measure belt tension by analyzing the harmonic characteristic of the belt vibration. This will ensure constant and accurate readings, consistently. The suitable belt tension could be calculated based on its properties. Then the sonic tension meter could be used to check proper tension value. Having the proper tension for each belt is very important to ensure energy transfer with minimum losses.

Figure 4 Sonic Tension Meter Device

Figure 5 Wrong Tension Effect on Timing Belt

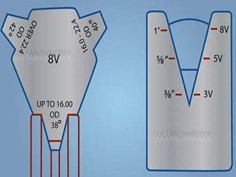

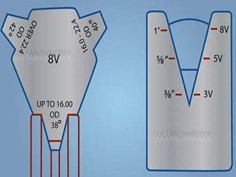

Belts & Pulleys Gauges

Replacing pulleys and belts on the proper time is very important. For example, if the pulley had excessive worn out and kept in service it will damage the belt due to its sharp edges. Visual inspection is not sufficient to determine if the pulley or the belt is worn out. Instead specific gauges should be utilized to determine the condition of the pulleys and the belts.

Figure 6 Worn out Pulley

Figure 6 Worn out Pulley Figure 7 Belts & Pulleys Gauges

Figure 7 Belts & Pulleys Gauges

Conclusion

Belt manufacturers usually design belts for a two-year lifecycle. Performing maintenance by utilizing the proper tools will enhance the maintenance quality of the fin fans, which will increase the equipment reliability, increase the mean time between failures, and reduce the maintenance cost.

Figure 1 Fin Fan Arrangement

Figure 1 Fin Fan Arrangement

Figure 6 Worn out Pulley

Figure 6 Worn out Pulley Figure 7 Belts & Pulleys Gauges

Figure 7 Belts & Pulleys Gauges

Hello Sultan, thanks a lot for this precise and spot on post. We recently completed a bad actor studies on Belt failures. Key factors we’re suspecting as one of the problems is Installion as it applies to correct Belt tension. We record belt snapping of up to six times in a year. Can you in anyway support with the most cost effective method to determine design belt tension values, and also any similar experience you’ve had and actions taken to reduce mean time to failure of Finfan belts.