Data Analytics & IIoT

Drive Smarter Maintenance and Better Operating Decisions by Collecting, Interpreting, and Applying the Right Data

With the rise of the fourth industrial revolution (Industry 4.0), a new world of possibilities has opened for manufacturers. Given this extraordinary evolution, it's inevitable that the shift must involve leveraging all the value inherent in available data.

- Pieter Van Camp

- I-Care Group

Terminology and Background of AI Systems

Do you know the difference between AI, machine learning, predictive analytics, data analytics, IIoT, and predictive maintenance? Jason Tranter goes into the definitions with examples…

- Jason Tranter

- Mobius Institute

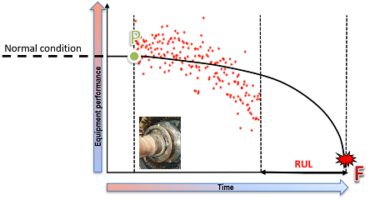

Bearing Problems – Fault Frequency and Artificial Intelligence-Based Methods

The early detection and fault analysis of bearing problems is crucial. When a rolling-element bearing develops flaws on the races and/or rolling elements, there are four vibration frequencies that can result...

- Pawel Lecinski

- CMRP

How to Transform Data into Insights

The transition to predictive maintenance becomes difficult if you are not able to generate and collect the right data. You need to be able to not only collect data, but to also analyze and visualize the data in a dashboard, so you can act on it right away.

- Pieter Van Camp

- I-Care Group

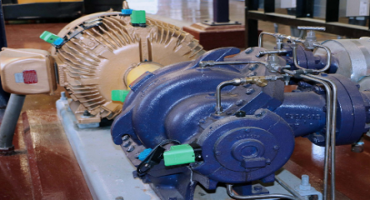

Nine Key Points to Execute a Successful Online Diagnostics Project

Industrial Internet of Things (IIoT) finds many application fields today in the industry by connecting assets to each other, gathering data and transferring it to other internet-enabled systems..

- Can Uslu

- PdMechanics

Training Machine Learning Models

When we’re training the model, we’re looking for normal behavior and, along with the client’s domain experts, come together with a model that represents the behavior they are trying to control…

- Robert Kalwarowsky

- Rob's Reliability Project

Preview the 2021 SMRP Annual Conference!

The Society for Maintenance and Reliability Professionals (SMRP) is preparing to welcome attendees for its 29th Annual Conference. Hear from SMRP Executive Director Erin Erickson about what's in store for attendees at this year's event.

- SMRP

Everactive Solution Offers 24/7 Screening Tool to Optimize Vibration Programs

The benefits of wireless monitoring can be boiled down to a simple premise—optimizing maintenance resources to maximize uptime and reduce costs. Real-time awareness lets you direct resources when and where they are needed.

- Tom Ross

- Everactive

How Important is a Bill of Materials?

The key to effective asset and maintenance data management is accuracy. An EAM system can only do so much with poor quality data and the same applies to BoMs. BoMs can provide accurate material information in real time to ensure all parts are stocked and identifies which parts are needed to complete work orders.

- Adanna Anyalachi

- HubHead

- 1

- 2

- 3

- 4

- 5

- 6

- 7