Precision and Proactive Skills

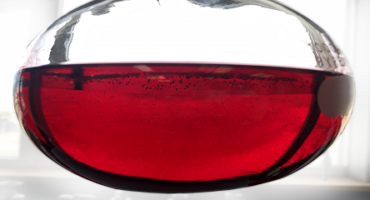

Why Filter Industrial Oil

As much as 70% of all premature machine failures can be attributed to contamination. To prevent these failures, it is important to purify the new oil as it comes into the facility and then keep it clean throughout its life. By establishing an ISO code cleanliness goal and maintaining it, you will extend the life of the oil and the equipment..

- Preston Rubottom

- Lubrication Engineers

Concepts of Balancing – Rotational Unbalance

Rotational unbalance occurs when there is an uneven distribution of mass around an axis of rotation. This quick tip will explain the possible causes of unbalance…

- Tim Sorensen

- ACOEM

The Key to Machinery Reliability

The goal of Minnkota’s PPM (planned preventative maintenance) Team is to use their technologies and resources to provide the workers with safe, reliable operating equipment and make a positive impact on their maintenance...

- Tod Baer

- Minnkota Power Cooperative Inc.

Alignment Check vs. Alignment

One question that arises regularly in training is about doing alignment checks. Is it okay to just check the alignment? This quick tip will address the reasons for alignment check...

- Stan Riddle

- ACOEM

The Enemy of Reliability: Over Lubrication

Up to 40% of bearings are killed by over lubrication, and another 10–20% are killed by under lubrication. If this is true at your facility, the fault is caused by human error...

- Tom Murphy

- SDT

Keep Your Hydraulic Oil Clean and Dry to Ensure Reliability

One of the best ways to ensure smooth-running hydraulic systems is to use the right hydraulic oil and keep it clean and dry. Hydraulic systems have become more sophisticated in recent years, as speed and pressure have …

- Scott Leipprandt

- Lubrication Engineers

The Drop Point and Lubrication Contamination

Are you familiar with the term "drop point" of a grease? The drop point is the temperature at which the oil and the soap, which are the two main elements in grease...

- Tom Murphy

- SDT

Getting Started

Welcome to the home of reliability improvement; RELIABILITY CONNECT! The community is designed to provide you with educational articles, videos, and podcasts...

- Jason Tranter

- Mobius Institute

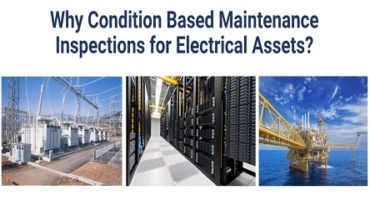

Why Condition Based Maintenance Inspections for Electrical Assets?

Electrical inspections must be performed on energized equipment to accurately ascertain the health of the equipment. Traditional inspections of energized equipment are time consuming, risky and costly for...

- Rudy Wodrich

- IRISS

- 1

- 2

- 3

- 4

- 5