Implementation Strategy

Join Us at Reliable Plant Conference 2025!

The Reliable Plant Conference & Exhibition, co-located with the Machinery Lubrication Conference & Exhibition, is a 4-day event dedicated to the latest trends and tactics in maintenance and reliability. With expert-led learning sessions, access to cutting-edge tools and technologies offered by over 100 exhibitors, and powerful networking experiences, this is a can’t-miss event for anyone looking to transform their maintenance strategy.

- Noria Corporation

RCM Graphs and P-F Interval Graphs – Are they useful?

RCM graphs and P-F interval graphs, of one form or another are often cited as the basis for an effective maintenance and reliability program. But are they useful?

In this podcast we’ll explore the use of these representations and how they can be used tactically and strategically to better manage an industrial operation.

- Ron Moore

- RELIABILITY CONNECT

Myths and Pitfalls of Planning & Scheduling – CONNECT Conversations

We’ll be reviewing the various pitfalls and myths associated with effectively installing a CMMS. For example, if the total number of defects coming into the process on a daily basis overwhelm your ability to effectively plan and schedule, the system will fail. We’ll review the importance of defect elimination, especially upstream of maintenance in operations and design, the importance of have a proper PM program, a proper condition monitoring program, the importance of integrating the production plan and the maintenance plan into a single plan, among other issues...

- Ron Moore

- RELIABILITY CONNECT

Expectations, Execution and Engagement – Essential – CONNECT Conversations

It’s been our experience that the lowest standard you set is the highest standard you can expect. As such, your expectations (standards) should be fairly high, but achievable. It does little good to set expectations too low – too easy, or too high – assuring failure....

- Ron Moore

- RELIABILITY CONNECT

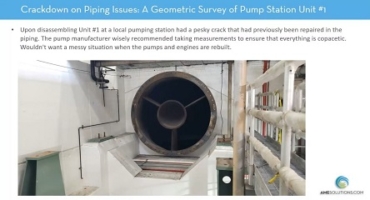

Crackdown on Piping Issues: A Geometric Survey of Pump Support Structure

The piping of this very large pump was about 10 feet in diameter, and structural cracks were forming. We measured the flatness of each individual bearing foot, and then measured that flatness against a best-fit plane of all four feet to check for soft foot. We also measured…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

Episode 23: Carl Sullivan

Welcome to VETERANS CONNECTED Season Two! Maintenance and reliability expert and military Veteran Eric Bevevino interviews E5 Sergeant, Carl Sullivan. Born and raised in Kentucky, Carl takes us through his unusual enlistment in the Kentucky Army National Guard that sparked the beginning of his military career. Eric and Carl discuss Carl's personal inspiration for joining the National Guard, his connection to the Honor Flight Network, and his efforts to establish the innate value in veterans at Lexmark...

- Eric Bevevino

- Veterans Connected

Sensor Fusion: The Path to Proactive Plant Maintenance and Operational Excellence

A powerful approach for improving plant maintenance programs is the integration of multiple sensing technologies to improve coverage of machines and different failure modes. This can be further complemented by effective analysis of the data from all the different sources. When using multiple sensors like this, it is called Sensor Fusion...

- Alan McCall

- Sensoteq

The Benefits of Quantifiable Measures in Reliability Strategy Execution

Being able to take the next step in executing a reliability strategy often entails quantifying the value of taking on the effort. Often, there are subjective measures assigned, such as internal or external audit criteria, and some score that comes because of these audits. Where the rubber really hits the road is when we can connect the dots between what we are trying to accomplish and some clear and measurable source of value...

- Mike Gehloff

- Allied Reliability

Unlocking the Potential of Asset Management: Your Guide to a Productive Future

A well-structured asset hierarchy is essential for a strong reliability program foundation. If you're struggling to distinguish between effective and ineffective aspects of your operation or identify areas for enhancement, it's likely your asset hierarchy that needs attention...

- Reliability and Asset Management Experts

- Life Cycle Engineering

- 1

- 2

- 3

- …

- 8