Defect Elimination

How Consistently Designed Procedures Can Save Lives, Time, and Money

Procedures are a series of steps followed in a regular, definite order, and most people complete the steps of multiple procedures every day. Whether they’re written down or internalized, procedures are organizational tools that help people safely and accurately complete tasks..

- Daryl Brister

- Shea Capability & Compliance Solutions

Remembering the Past, Thinking about the Future, Being in the Present

For a reliability engineer, focusing on the past and the future will allow you to learn from what has happened in the past and what might happen in the future. It will then generate a list of actionable items to work on in the present..

- Tim Rice

- The Defect Elimination Project

ODS (Operational Deflection Shape) Analysis, When and Why?

In this Interview Mohamed Wahba explains Operational Deflection Shape is a magical tool can be used to solve the most complicated resonance problems, however not much analyst use it due to lack of knowledge or is not supported by their companies with software and measuring module. Motion amplification camera becomes more trendy, nevertheless, its cost and some technical limitations make ODS in competition.

- Mohamed Wahba

- EzzSteel

Co$t Cutting who runs this technological marvel

Have a look at the world the technologically advanced world we have - since the industrial revolution you've got to say we've come a long way. So who runs this technological marvel (this guy - the bean counter) he's in charge.

- Dare Petreski

- Delta Asset Reliability

Defect Elimination of a Beat Vibration that Showed up Across the Entire Plant

What young Ashley was telling me it just shakes? I said why do not we do just a little bit of investigation and solve the problem. He said you cannot solve it; it is been shaking like this for 2 years. I said between us I think I can solve this. There is no problem at all it was a beat vibration. Beat vibrations show up across the plant and I will talk about beat vibrations later in the video.

- Dare Petreski

- Delta Asset Reliability

Trick Question: Do You Want Value or Low Costs?

If you can’t sell all you can produce, then reducing costs is often the only way to improve margins, but that simplistic accounting perspective is not always the case. Cost control is often thought to be key to attaining profitability, but in the case of maintenance it can get you into trouble...

- James Reyes-Picknell

- Conscious Asset

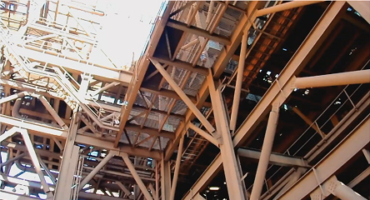

Design for Reliability: Eliminate the Defects Before They Become a Reality

If we were to ask management where most of the defects come from in our plants, they might say poor maintenance or poor operating practices. If you asked those performing maintenance and operating the equipment, they will probably say they are doing the best with what they were given...

- Tim Rice

- The Defect Elimination Project

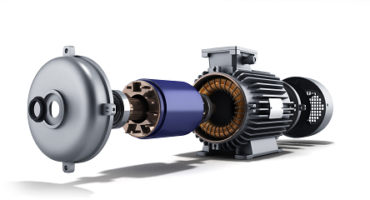

Trust Your Technology – Trust Your Expert

A fault identified on a 1250HP electric motor showed that while we have proven technologies at our fingertips, we still often use our emotion (gut feeling) to make a call regarding our asset’s health...

- Tim Rice

- The Defect Elimination Project

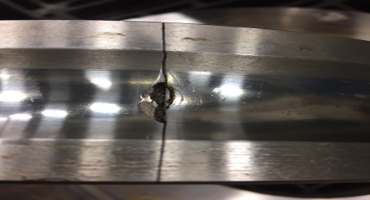

Defect Elimination of Dust Contamination and Lubrication Cleanliness in Ore Operation

Were refilling the remote crusher that’s the lube tank with about 5000 liters of lubricant in there and that’s the stuff (dust) sitting on top. That with just my finger just trying to figure out how much dust is sitting on top. And that’s the seal; the rubber seal that actually stops the dust from getting in.

- Dare Petreski

- Delta Asset Reliability

- 1

- 2

- 3

- 4

- 5