Defect Elimination

Motion Amplification in Action: A Closer Look

Jeff Hay, the CEO of RDI Technologies, discusses Motion Amplification; a camera based technology invented by RDI. Jeff believes that the camera is the sensor of the future because visualization is faster, safer, and makes the complex more simple. Since starting RDI, he has created and patented multiple methods for using camera technology to visualize and measure motion.

- Jeff Hay

- RDI Technologies

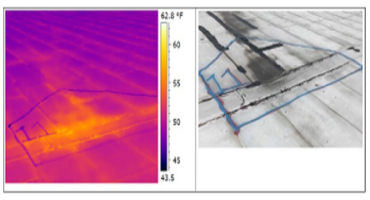

Cost Avoidance Within the Infrared World

Who does cost avoidance? What is it? Where would you apply it? Why would you worry about it? These are the questions that one should ask themselves. Most of the time is spent doing the physical work and analyzing that data to determine the condition or health of the equipment rather than thinking what our group did to save the company money. This article explains the methodology we used and why you should care about cost avoidance.

- Patricia Warner

- Cummins Inc.

How to Troubleshoot a Variable Speed Drive and Motor Circuit

Do you have a Drive that’s tripped and you don’t know if it’s the Motor? A variable speed drives (Variable frequency Drive) are often built with current transformers monitoring each phase for current balance or over current, and will trip on a predefined limits.

- Mark Gurney

- 3Phi Reliability

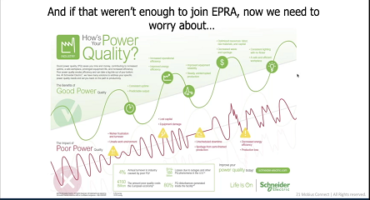

What Are the Costs and Effects of Poor Power Quality?

Alan Ross, president of EPRA, gives an overview of the causes of poor power quality, the sectors that are most affected, and the cost of outages…

- Alan Ross

- Electric Power Reliability Alliance EPRA

Reliability Centered Lubrication May Turn Out to be Your Best Investment so Far

Many issues with industrial assets are inextricably connected to lubrication. Too little lubrication, too much or simply using the wrong product.

- Wouter Bogaerts

- I-Care Group

Condemning a Motor Using MCA™

Experience has shown that 20 to 40 percent of motor systems tested may have some sort of alarm condition. Just because a motor has exceeded the alarm limits in MCA Basic™ or MCA PRO™ it does not necessarily mean the motor will fail or should be stopped immediately. For over 30 years the dedicated staff at ALL-TEST Pro have gathered data and resources to determine when a motor will most likely fail on the most common 3-phase squirrel cage motors.

- Mark Koch

- ALL-TEST Pro, LLC

Tools RCM

Reliability Centered Maintenance is a reliability tool used to develop a complete and comprehensive maintenance strategy based failure modes and the context and environment in which you operate the equipment. RCM (Reliability Centered Maintenance) has been around since the mid-60’s, and if effectively applied in an ideal world would lead to exceptional reliability. In fact, RCM has been applied very effectively in the airlines and nuclear industries - both have potentially enormous consequences in the event of an unplanned failure.

- Doug Plucknette

- RELIABILITY CONNECT

Check Sheets- Something is Missing, I Think…

Have you ever completed an infrared survey and wondered if you’ve missed something that should have been inspected? Do you know the special safety instructions to open certain electrical cabinets? Has management ever asked you when was the last time that you’ve inspected a specific cabinet and you couldn’t answer them? If you have answered yes to any of these questions, you need to develop a check sheet for the equipment that you inspect.

- Patricia Warner

- Cummins Inc.

How to Detect Early Stage Defect Using I-DNA Technology

Learn how to use Predictive Maintenance in your industrial environment, and see the benefits of putting I-DNA Technology Algorithms into your Predictive Maintenance Program.

- Pieter Van Camp

- I-Care Group

- 1

- 2

- 3

- 4

- 5