Continuous Improvement

How Motion Amplification® Fits into a Reliability Program

If you want the equipment and assets in your industrial facility to stay up and running, you’ll need a good reliability program. Reliability programs are designed to increase and maintain the performance of a plant’s equipment by identifying potential failures and eliminating their causes and reducing the possibility of production failures and stalls while enhancing safety.

- Jeff Hay

- RDI Technologies

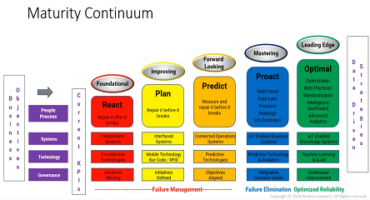

Where Does Your Plant Fall on the Maturity Continuum?

When I talk to clients, the first thing I do is find out where they are now – are they mostly reactive, do they plan most of their maintenance, do they do some PdM, etc.? On this continuum, I outline…

- John Pucillo

- True Reliability

Complicated Versus Complexity in Maintenance

I’ve always thought that knowing when something was going to fail was unknowable. Of course, predictive maintenance vendors shout from the rooftops about the effectiveness of their technology. Even the onboard computers tell you to replace components, somehow knowing when the failure will occur.

But really, most failures are not related to wear or aging, so how can we know what is going to happen and when? This discussion leads me into the sales pitches for AI (Artificial Intelligence). Can we ever get to the point where there is so much data that we can really predict the future?

- Joel Levitt

- Springfield

Preview the 2021 SMRP Annual Conference!

The Society for Maintenance and Reliability Professionals (SMRP) is preparing to welcome attendees for its 29th Annual Conference. Hear from SMRP Executive Director Erin Erickson about what's in store for attendees at this year's event.

- SMRP

Condition Monitoring Technologies – Pros and Cons of the Top Five

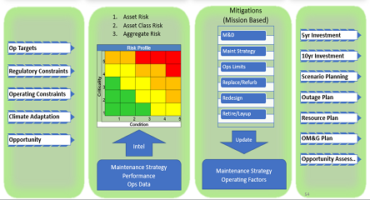

There are several different technologies that can be used, alone or in combination, to monitor the condition of your machinery from a predictive maintenance (PdM) perspective. The criticality of the machine affects the number of such inspection-type technologies that are applied to a given failure mode. The more critical the machine and the more critical the failure mode, the more redundancy you will want in the inspections.

- Timothy Weilbaker

- Allied Reliability, Inc.

Wireless Vibration Measurement Systems

Pieter van Camp discusses the benefits of a wireless system to measure vibration.

- Pieter Van Camp

- I-Care Group

It’s 2021, and You’re Still Struggling to Keep Up with EAM/CMMS Fundamentals

EAM and CMMS systems are essential to the survival of asset-intensive companies. In a highly digitized era, this is not novel information. The key to extracting the full value from an EAM or CMMS system is managing it properly. Even though EAM/CMMS systems have been on the market for a long time, many companies still struggle with the basics of maintaining their systems.

- Adanna Anyalachi

- HubHead

Probability and the P-F Curve

Often when talking with Maintenance and Reliability professionals, a popular topic of discussion is how frequent a particular inspection task should be performed. This also comes up often when discussing Preventive Maintenance Optimization (PMO). In this post, I'd like to present a risk-based approach to calculating the proper frequency of a On-Condition Inspection task.

- Bill Barto

- RELIABILITY CONNECT

Excuse Me, This Is Not What I Ordered

Asset-intensive companies rely heavily on BoMs for work orders and maintenance operations. The accuracy of your work order depends on having the correct parts and quickly identifying those parts. Time is money for every organization. Therefore, maintenance personnel do not need to be spending unnecessary extra time trying to locate equipment. Having a BoM is only half the battle. BoMs are often laced with misinformation, missing parts, and errors which hinders maintenance and reliability operations.

- Adanna Anyalachi

- HubHead

- 1

- …

- 7

- 8

- 9

- 10

- 11

- 12