Continuous Improvement

Software Reliability

Software reliability is the probability that software will operate failure-free for a specified period of time in a specified environment. It is an important contributing factor impacting system reliability (which includes hardware and human reliability).

Five Things That I’ve Learned in Five Months in Maintenance & Reliability Talent

After spending nearly two decades helping people solve problems related to physical assets and asset reliability, earlier this year, I decided it was time for a change and stepped into the maintenance and reliability talent acquisition and staff augmentation field.

- Adrian Messer

- Progressive Reliability, LLC

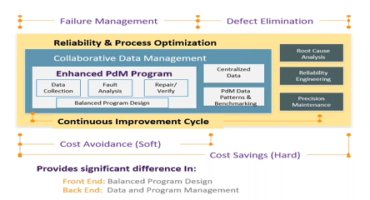

Using PdM to Drive Reliability Improvement

PdM programs manage failures – they do not usually improve reliability. John Pucillo wants to change this. Here, he describes how your PdM program can be used to drive reliability and provides examples…

- John Pucillo

- True Reliability

CMMS, EAM, Who Cares?

In many ways, the "CMMS vs EAM" distinction has become outdated and misleading. Most CMMS’ today have EAM functionality, after all, and most EAM tools are necessarily also CMMS.

- Frederic Baudart

- Accruent

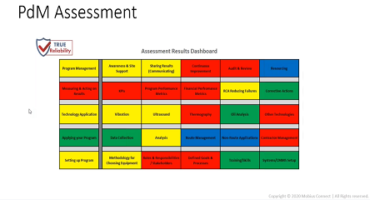

Why You Should Perform a PdM Assessment

If your plant has a long-standing PdM program, I recommend performing an assessment. I encourage people to do self-assessments, but you may at some point wish to bring in an outside professional to perform an overall program assessment. It’s kind of a score card…

- John Pucillo

- True Reliability

7 Steps to Assess Your Organization’s Readiness for Industry 4.0

In the ideal world of Industry 4.0, organizations will have better equipment with wireless connections and sensors linked to a system that can visualize and control the entire production line and make autonomous decisions. Industry 4.0, in other words, describes the ever-increasing trend towards automation and data exchange.

- Tom Rombouts

- I-care Group

Brewery Saves Big by Extending Compressor Oil Life

With regular oil analysis to ensure oil quality and cleanliness, the drain intervals for all four air compressors were extended up to eight times the OEM-recommended interval of 8,000 hours. Total cost savings – on oil alone – was $71,000. Environmental impact was reduced as well, with 1,035 fewer litres (273 fewer gallons) of waste oil. Fewer oil changes also meant less downtime, maintenance and labor. The overall effect for the company was significant cost savings on oil, maintenance time and disposal.

- Preston Rubottom

- Lubrication Engineers

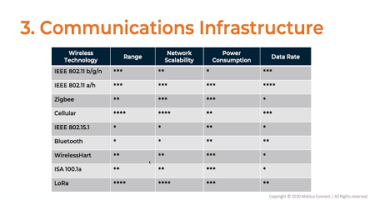

How Your IIoT Communication Infrastructure Can Optimize ROI

In the IIoT world, it’s hard to keep up with the fast-changing technology. But your communication infrastructure can have a significant influence on the success of your project, as it can take up to 50% of your resources…

- Dries Van Loon

- NanoPrecise

Detect- Solve- Improve (a New Way of Reliability)

Today, we kick it off with our new slogan DETECT - SOLVE - IMPROVE.

- Will Bower

- Maintain CM Ltd

- 1

- …

- 6

- 7

- 8

- 9

- 10

- …

- 12