Continuous Improvement

Transform Learning into Results

Tara Holwegner goes through the Apply phase of her 3A Learning model, which involves aligning the learning strategy to the company culture so that it is sustainable…

- Tara Holwegner

- Life Cycle Engineering

What Can 3A Learning Do for Your Company?

Tara Holwegner introduces her 3A Learning model and explains the steps…

- Tara Holwegner

- Life Cycle Engineering

Choosing the Right Learning Intervention for Your Budget and Goals

Tara Holwegner explains the Assimilate phase of her 3A Learning model and provides guideposts for selecting the right type of learning for your company’s objectives…

- Tara Holwegner

- Life Cycle Engineering

Hiring a Reliability Consultant

What industrial organization doesn’t want to improve safety performance, decrease downtime, and improve throughput while optimizing cost? Even if you think you are running at full potential, the competition looms: How do you stay ahead?

- Michael Gehloff

- Allied Reliability

The Fundamentals of Belts and Sheaves

In some industries, like oiling, drive belt replacement is considered a task for the new guys on the floor. It’s an easy job right? Absolutely. But there are many ways to do it incorrectly if not taught properly the first time.

- Stan Riddle

- ACOEM

7 Essential Predictive Maintenance Indicators (KPIs) to Track

Maintenance KPIs are performance metrics that help you measure your overall maintenance process. These indicators evaluate factors critical to an organization's success. However, not all managers know the best indicators for this and may fail to monitor essential data to increase production potential.

- Silvio DosSantos

- SEMEQ

The Industry 4.0 Roadmap and How I-care’s Approach Is Different

Industry 4.0 is what organizations are all striving for, but it’s not something that can be fixed overnight. To achieve sustainable results, a long-term mindset is needed. It is therefore essential to choose a strategic approach taken in stages. And, of course, the right partner to help you guide all facets of your organization through this major transition.

- Tom Rombouts

- I-care Group

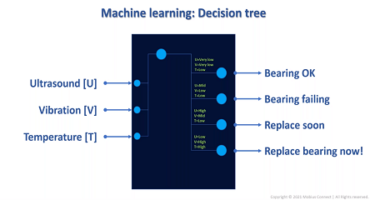

How Exactly Does Machine Learning Work?

Have you ever wondered exactly how machine learning works? Where does the system get the data for equipment that is not allowed to fail often? Jason Tranter goes into a method an AI system might use to tell us whether a bearing is about to fail…

- Jason Tranter

- Mobius Institute

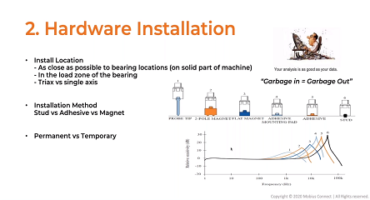

For Maximum ROI, Check the IIoT Hardware Installation

Once we’ve selected the assets and the appropriate technology, it’s time to look at hardware installation, since we know our analysis is only as good as our data. There are many sensors in the market today and they all promote ease of installation, but a proper installation will determine whether you get actionable results…

- Dries Van Loon

- NanoPrecise

- 1

- …

- 5

- 6

- 7

- 8

- 9

- …

- 12