Condition Monitoring

Aluminum Complex Thickener Greases

Lubricant has the power to increase equipment uptime and enhance bottom line profitability.

- John Sander

- Lubrication Engineers

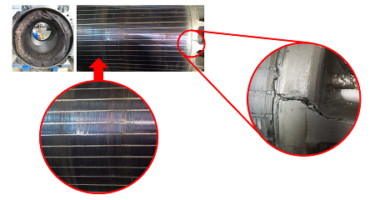

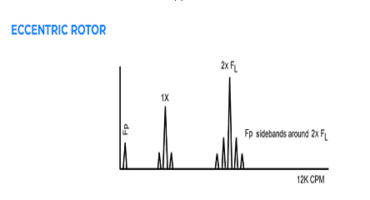

Electrical Frequencies Calculation and AC Motor Faults Patterns. Part 2

In the Part 2 the practical example will be analyzed.

Let’s look the background and calculate the most common frequencies produced by motor that potentially will be required for further analysis.

- Pawel Lecinski

- CMRP

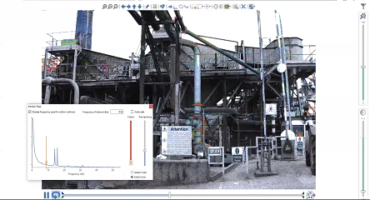

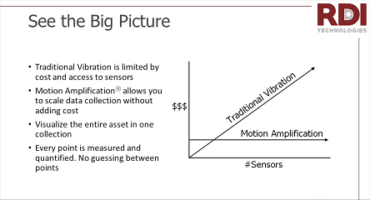

Demo of Motion Maps and Frequency Filtering

Motion amplification allows you to see things a normal camera can't show. These amplifications show you all frequencies but also allow you to isolate individual frequencies, and visualize faults. The program is user friendly, color coded, and gives you vibration data in an easy to export Mp4 format.

- Jeff Hay

- RDI Technologies

Resonance & Natural Frequency

Have you ever tried to balance a fan and its vibration won’t go down? No matter what you do, do you know what Resonance is?

3 Tips to diagnose Resonance and 6 ways to correct it below.

- Dr. Thierry Erbessd

- Erbessd Instruments

Fundamental Measurement of MA

Imagine each pixel on a camera becomes a sensor; you can now measure millions of data points. The fundamental measurement of Motion Amplification is displacement, which increases capabilities of measurement types and allows you to easily use it with other technologies to extract vibration data.

- Jeff Hay

- RDI Technologies

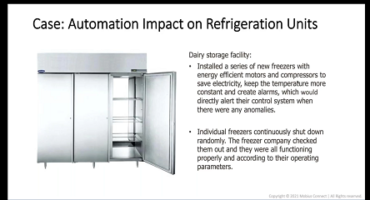

Impact of Automation on Refrigeration Units and the Role of Power Quality

Alan Ross, president of EPRA, presents a case study involving a dairy storage facility. When they installed a series of new freezers with energy-efficient motors and compressors, and they automated the system, individual freezers began shutting down randomly…

- Alan Ross

- Electric Power Reliability Alliance EPRA

Condition Monitoring Technologies – Pros and Cons of the Top Five

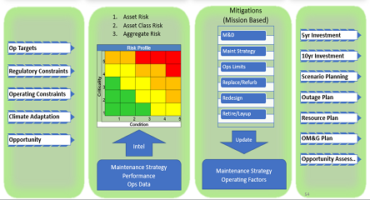

There are several different technologies that can be used, alone or in combination, to monitor the condition of your machinery from a predictive maintenance (PdM) perspective. The criticality of the machine affects the number of such inspection-type technologies that are applied to a given failure mode. The more critical the machine and the more critical the failure mode, the more redundancy you will want in the inspections.

- Timothy Weilbaker

- Allied Reliability, Inc.

Electrical Frequencies Calculation and AC Motor Faults Patterns. Part 1

The fault diagnosis of induction motors, being probably the most common drivers used for industrial machinery plays an important role to reduce the catastrophic failures and production lost tonnage.

- Pawel Lecinski

- CMRP

What Happens When Failure Codes Are Set Up Incorrectly?

When failure codes are set up correctly, they can help you gather valuable information pertaining to your company’s assets that promotes preventative and efficient maintenance. This information can be applied to work orders and used for reliability analysis. However, when your failure codes are not correctly set up in SAP or Maximo this can impact your assets, your maintenance operations, and your ROI.

- Rhiana Safieh

- HubHead Corp

- 1

- …

- 6

- 7

- 8

- 9

- 10

- …

- 19