Condition Monitoring

The Fundamentals of Belts and Sheaves

In some industries, like oiling, drive belt replacement is considered a task for the new guys on the floor. It’s an easy job right? Absolutely. But there are many ways to do it incorrectly if not taught properly the first time.

- Stan Riddle

- ACOEM

Using APIs- Integrate Data from Different Platforms with Your Condition Monitoring System

APIs are a set of functions and procedures that are used to create applications. They link different software platforms together and let unrelated applications exchange information.

- Anders Hultman

- SPM Instrument AB

Do Employers Prefer Experience or Certification?

The question: When you are looking to hire a person, which factor is the most important – experience or certification – if you can only choose one or the other? Our panel answers and gives some valuable advice…

- Matthew Moore

- Moore Reliability Limited

Introducing: AssetWatch, Formerly Known as Nikola Labs

Today, Will Zell and Jaidev Krishnan sit down to introduce AssetWatch, formerly known as Nikola Labs. Nikola Labs started out as a company that was focused on wireless power transfers. Now, as AssetWatch, they attack the problem of unplanned downtime, and eliminate it forever.

- Jaidev Krishnan

- AssetWatch

Condition Monitoring and Energy Saving

This weeks podcast we talk about how Condition Monitoring can have a big impact on Energy Savings.

- Will Bower

- Maintain CM Ltd

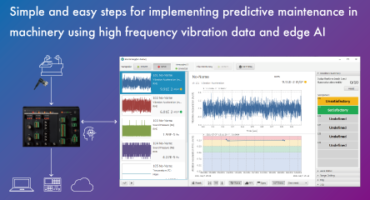

Simple and Easy Steps for Implementing Predictive Maintenance in Machinery using High Frequency Vibration Data and Edge AI

Currently, the most commonly used standard for maintenance processes is Time-based Maintenance (TBM) that involves inspection, repair, and part replacement at regular intervals. In general, TBM is not optimal and cost effective. On the other hand, Condition-based Maintenance (CBM) involves the utilization of various types of sensor data collected from machines to perform repairs or other countermeasures before malfunctions or anomalies occur, hence reducing the unnecessary cost of maintenance.

- Vikas Kumar Singh

- Macnica

The New Normal in Predictive Maintenance

What does machine health monitoring look like in an era of the online workday, personnel shortages, and supply chain hang-ups? These recent trends have influenced practices in predictive maintenance—including how data is collected, shared, and analyzed. Read on for five condition monitoring solutions to avoid manufacturing delays and optimize workflow.

- Bob Martin

- IMI Sensors

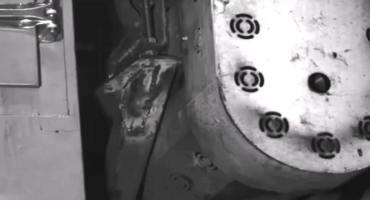

Motion Amplification Case Study: Structural Looseness

This case study features a convection oven fan used in the customer's production process. Multiple welds and other repairs were made prior to the inspection. A service team was called in to balance the fan, but with Motion Amplification it quickly became clear that there was a serious structural issue.

- Andrew Dougherty

- RDI Technologies

Vibration Analysis- The Tools for Success

We dive deep in conversation about our experiences in vibration Analysis and why we think it is so important for industry.

- Will Bower

- Maintain CM Ltd

- 1

- 2

- 3

- 4

- 5

- 6

- …

- 19