Condition Monitoring

C&W Services Deploys Wireless Predictive Maintenance to Fix a Dated Walkaround Program

C&W Services implemented a wireless and AI-based predictive maintenance (PdM) solution from Petasense at a leading pharmaceutical and biotech client’s facility to automate data collection, improve asset reliability, reduce equipment downtime and achieve better resource allocation by continuous monitoring of critical machinery...

- Ken Madsen

- Petasense

Machine Monitoring and How ESA Technology Can Upgrade Your Plant’s Reliability

In many cases, the quality of the power supplied to the motor system may be the cause of a breakdown or failure. The result of poor “power quality” is usually long term and often overlooked as the source or contributor to the problem. Knowing the quality of the incoming power, along with the mechanical and electrical condition of motor and the mechanical condition of the drive are important at all facilities to maintain uptime & save money...

- Bill Kruger

- ALL-TEST Pro

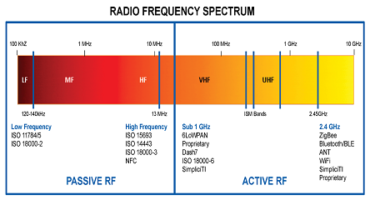

iCOMOX: Connectivity Options and Application

The Intelligent Condition Monitoring Box also known as iCOMOX is an open-source sensor fusion platform designed for Condition-based Monitoring (CbM) applications. The iCOMOX can measure vibration, sound, temperature, and magnetic field displacement. This device can...

- Richard Matsick

- Analog Devices, Inc

CbM Technology Trends and Solution Requirements

Dara O’Sullivan, System Applications Manager at Analog Devices, answers questions about CbM technology trends as well as how to get application insights and choose the best sensing solution for your system requirements.

- Dara O'Sullivan

- Analog Devices, Inc

Tying Reliability Programs Into Corporate Goals

Cost avoidance? Sure, why not. However, it is a method that has been continuously used through a great many programs that have gone the way of a great many programs.

- Howard Penrose

- MotorDoc LLC

A Condition Monitoring Toolbox for Gearboxes

When measuring on a gearbox with a vibration transducer, you almost always see a clear gear mesh signature in the spectrum; regardless if the gearbox is in mint condition or an older, worn gearbox, you still see the gear mesh. The mechanical explanation of this phenomenon can be found when studying the interaction of the teeth involved...

- Tim Sundstrom

- SPM Instrument

Continuous Condition Monitoring Pays off at a Large Power Utility

A large power utility in Hawaii was looking for more frequent condition monitoring on their Balance of Plant (BOP) generation assets. They had experienced significant equipment failures that occurred between their scheduled quarterly walkaround condition monitoring routes. They decided to trial Petasense technology on 8-10 assets...

- Ken Madsen

- Petasense

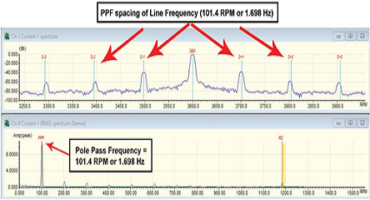

Rotor Bar Analysis Using Electrical Signature Analysis

Broken or fractured rotor bars are found as elevated Pole Pass Frequency (PPF) sidebands of line fre- quency (LF). PPF is calculated using the synchronous speed minus the running speed times the number of poles..

- Mark Koch

- ALL-TEST Pro, LLC

Remote Condition Monitoring

In this Interview Josiah share's his passion about using new methods to address persistent problems and many plants are unaware of the benefits that they could be reaping from such technology..

- Josiah Carter

- Advantage Reliability Services

- 1

- …

- 10

- 11

- 12

- 13

- 14

- …

- 19