Five Minute Facts

Boldly Proclaim Your Reliability Progress

You deserve recognition for your reliability successes. If your program is being overlooked, you will need to take the initiative and ensure the rest of the plant – and senior management – is aware of what you are doing…

- Bill Barto

- RELIABILITY CONNECT

Reliability Program Bad Actors

Without resolving bad actor issues, endless man-hours and revenue are at risk of being expended.

- Jeff Hay

- RDI Technologies

How Certification Programs Work (and How They Should Work)

The idea of certification is to earn a credential that is respected, is fair and independent, and represents a true achievement. In our professional lives, we need a goal to aspire to, and we should have recognition for our achievements…

- Jason Tranter

- Mobius Institute

How to Harness the Power of Direct Motivation in Your Plant

When it comes to implementing reliability improvement, it is important to remember that reliability happens out in the field, not in an office or a webinar. It is important to get everybody, particularly those closest to the work, involved in the process.

- Michelle Henley

- TMG Frontline Solutions

How to Harness the Power of Direct Motivation in Your Plant

Michelle Henley gives you the questions you should be asking to ensure you maximize the power of direct motivation (the three P’s) among frontline workers in your plant and minimize the possible damage inherent in indirect motivation…

- Michelle Henley

- TMG Frontline Solutions

Filtration Prolongs Oil Life, Protects Equipment

Filtering new and used oil prolongs oil life and protects equipment from wear.

Studies have shown that as much as 70% of all premature machine failures can be attributed to contamination. To prevent these failures, it is important to purify the new oil as it comes into the facility and then keep it clean throughout its life. By establishing an ISO code cleanliness goal and maintaining it, you will extend the life of the oil and the equipment.

- Preston Rubottom

- Lubrication Engineers

Continuous Monitoring Systems: Choosing the Frequency of Data Collection

The chemical processing industry incorporates a broad range of machinery, both rotating and reciprocating, which are monitored using various types of sensors and other advanced technologies that measure equipment performance/health. The determining factor as to what must be monitored and how to do so is the criticality of the equipment, based on its importance to the process and/or operation.

- Ernest McCurdy

- T.F. Hudgins (division of Allied Reliability)

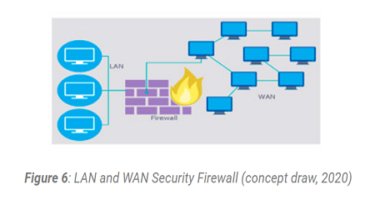

The Reliability Engineer’s Guide to Understanding IIoT Device, LAN, and WAN Security

As wireless sensor technology begins to take the leading edge within the industrial internet of things community, a new era of data security has emerged that requires diligent thought and consideration on the part of end users, system integrators, and key stake holders. Critical machine health and process data being transmitted wirelessly and hosted internally as well as externally creates an entirely new series of security concerns that must clearly be understood to maximize the value of the technology. This presentation will focus on the key security tools available to end users to ensure the security of their data when deploying wireless sensor networks and hosting data internally as well as externally to their organizations.

- Michael Howard, DSc

- ERBESSD-INSTRUMENTS

Let’s Talk About Food Grade Grease

Food grade grease offerings can play a significant role in preventing costly damage brought on by severe operating conditions in food, beverage and pharmaceutical applications.

- John Sander

- Lubrication Engineers

- 1

- …

- 5

- 6

- 7

- 8

- 9

- …

- 17