Five Minute Facts

What Makes a Good Leader?

A leadership panel – Doug Plucknette, George Mahoney, Rendela Wenzel, and Scott Brown – from Week of Webinars North America 2021 discusses what makes someone a good leader…

- Doug Plucknette

- RELIABILITY CONNECT

Don’t Expect Them to Know Your Metrics – Learn Theirs

You want to be recognized for your reliability work, but senior management may not understand the metrics you use, such as MTBF. To show your progress, you must speak their language. Bill Barto gives an example from his experience with theme parks…

- Bill Barto

- RELIABILITY CONNECT

7 Steps to Assess Your Organization’s Readiness for Industry 4.0

In the ideal world of Industry 4.0, organizations will have better equipment with wireless connections and sensors linked to a system that can visualize and control the entire production line and make autonomous decisions. Industry 4.0, in other words, describes the ever-increasing trend towards automation and data exchange.

- Tom Rombouts

- I-care Group

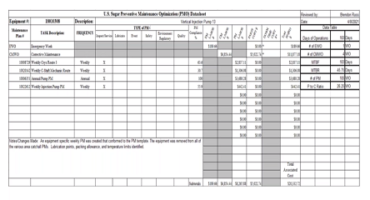

How to Perform PMO

You might have tens of thousands of assets, and those assets have tens of thousands of PMs. You won’t be able to devour the entire elephant at once and will have to take one bite at a time, so that’s where…

- Brendon Russ

- U.S. Sugar

The Business Case for Predictive Maintenance

When making a business case for predictive maintenance, you must first ask what management want. You should then ask what the employees want. Jason Tranter explains…

- Jason Tranter

- Mobius Institute

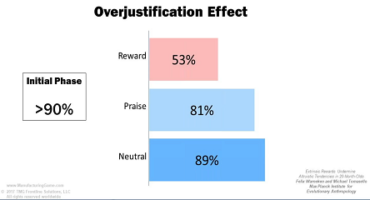

Certain Types of Motivation Actually Damage Work Performance

Michelle Henley has spoken about direct motivating factors (the P’s) and indirect motivating factors (the E’s). One of these enhances performance at work, and one actually decreases it. Scientific research backs this up, showing that…

- Michelle Henley

- TMG Frontline Solutions

Why Is an EAM Migration the Perfect Time to Correct Your Failure Codes?

If you are planning an EAM migration, then this is the perfect time to correct your failure codes. If your failure codes are not set up correctly this can impact your company’s maintenance and operations. The ideal time to correct your failure codes is before you load your master data into your new EAM system. By verifying your failure codes are set up correctly prior to your EAM migration, you will have ensured that the new EAM you are implementing is set up to support good maintenance practices.

- Rhiana Safieh

- HubHead Corp

How to Transform Data into Insights

The transition to predictive maintenance becomes difficult if you are not able to generate and collect the right data. You need to be able to not only collect data, but to also analyze and visualize the data in a dashboard, so you can act on it right away.

- Pieter Van Camp

- I-Care Group

Nine Key Points to Execute a Successful Online Diagnostics Project

Industrial Internet of Things (IIoT) finds many application fields today in the industry by connecting assets to each other, gathering data and transferring it to other internet-enabled systems..

- Can Uslu

- PdMechanics

- 1

- …

- 3

- 4

- 5

- 6

- 7

- …

- 17