Case Studies and Stories

Icon Water adopts sustainable approach to Asset Management

Icon Water supplies essential water and sewerage services to the Australian Capital Territory (ACT). It has served the community for more than 100 years and sources, treats and supplies water through a direct relationship with its customers..

- Jason Apps

- ARMS Reliability

Implementing IIoT-Based Asset Reliability Program at a Gold Mine

The wireless Predictive Maintenance program paid for itself within six months at a leading gold mining company. They demonstrated increases in asset reliability, personnel efficiency, and production as part of their digital transformation initiative...

- Ken Madsen

- Petasense

Continuous Condition Monitoring Pays off at a Large Power Utility

A large power utility in Hawaii was looking for more frequent condition monitoring on their Balance of Plant (BOP) generation assets. They had experienced significant equipment failures that occurred between their scheduled quarterly walkaround condition monitoring routes. They decided to trial Petasense technology on 8-10 assets...

- Ken Madsen

- Petasense

C&W Services Drives Asset Reliability-Based Culture Change at Pharmaceutical Client

C&W Services implemented Petasense’s Asset Reliability & Optimization system as a key piece of changing the reliability culture at a major pharmaceutical company. The results were dramatic, with 31 failures avoided in the first few months and zero unplanned downtime during the first half of 2019...

- Ken Madsen

- Petasense

Rotor Bar Fault Maintenance Issue: Vibration Sensor Alert

A 398 KW MV motor that runs a blower fan in a cement plant was showing strange behavior. The vibration equipment indicated vibration amplitudes that became chronic with the passage of time. The maintenance team not knowing what the issue was...

- Mark Koch

- ALL-TEST Pro, LLC

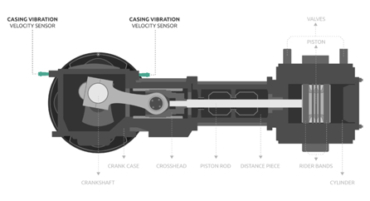

An Efficient Maintenance Strategy for Reciprocating Compressors

A client operates two reciprocating compressors, both of which are critical to the process. This particular plant produces a semi-finished product that is needed in another plant for the production of the end product. The reciprocating compressors are periodically inspected for rider band wear every 12 weeks, and to do so a shutdown is required.

- Lucas van Ruiten

- Istec International

Major Canadian Oil & Gas Company Extends Life of Operations

Major Canadian oil & gas company extends the life of operations with greater efficiency and reduced costs through OnePM. Problem: A leading Canadian oil & gas company had an offshore operation that was spending 50 percent more on maintenance than other company platforms in the same basin.

- Jason Apps

- ARMS Reliability

Major Global Oil & Gas Producer Improves Speed, Quality, and Cost of Maintenance Builds

A super-major oil and gas producer’s capital-project maintenance builds were costing too much and taking too long using a traditional maintenance-build approach, and the resulting maintenance strategies were of poor quality. The company was experiencing continual overspending, missed deadlines, and maintenance strategies that didn’t deliver the performance and reliability the operations team needed from the asset base...

- Jason Apps

- ARMS Reliability

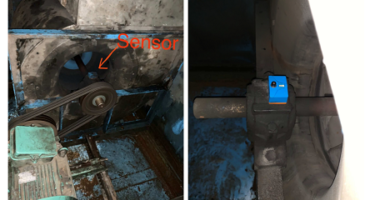

How to Include the Not-Approachable Equipment in CBM

It is always a challenge in the field of condition monitoring to monitor the machines which are not approachable, and that makes them prone to frequent failures.

- Akhil Jeet Rathore

- Indorama Eleme Petrochemicals Ltd

- 1

- 2

- 3

- 4