Case Studies and Stories

Simple and Easy Steps for Implementing Predictive Maintenance in Machinery using High Frequency Vibration Data and Edge AI

Currently, the most commonly used standard for maintenance processes is Time-based Maintenance (TBM) that involves inspection, repair, and part replacement at regular intervals. In general, TBM is not optimal and cost effective. On the other hand, Condition-based Maintenance (CBM) involves the utilization of various types of sensor data collected from machines to perform repairs or other countermeasures before malfunctions or anomalies occur, hence reducing the unnecessary cost of maintenance.

- Vikas Kumar Singh

- Macnica

Sustainable Predictive Maintenance for Improved Reliability of Car Manufacturing

This study provides brief details of an early warning system of an impending failure for an overhead conveyor in an automotive manufacturing plant in the US.

- Tumay Karaver

- Artesis Technology Systems

Stator Looseness

A 6.6 kV motor that is used to cool the temperature of gas after going through a gas phase polymerization process at a Petrochemical plant was experiencing abnormal symptoms. A technician conducted a vibration test and noticed an abnormal vibration...

- Mark Koch

- ALL-TEST Pro, LLC

Impact of Automation on Refrigeration Units and the Role of Power Quality

Alan Ross, president of EPRA, presents a case study involving a dairy storage facility. When they installed a series of new freezers with energy-efficient motors and compressors, and they automated the system, individual freezers began shutting down randomly…

- Alan Ross

- Electric Power Reliability Alliance EPRA

SKF ENLIGHT COLLECT IMx-1

Wireless technology is often perceived as being more expensive and less secure than traditional wired methods, but the opposite is true. Wiring can be at risk of damage in harsh environments, both during operation and maintenance so going wireless reduces the cost of installation, minimizes risk and is an affordable way to retrofit machines needing monitoring.

- Christian Sahlin

- LumenRadio

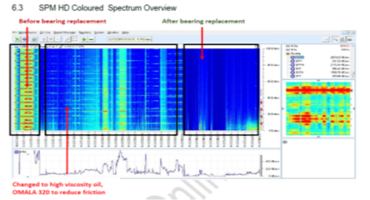

SPM Condition Monitoring Solution for Extruder

Welcome and enjoy the case study for extruder condition monitoring with SPM HD technology..

- Thamo Yellappan

- Eastwest Online (M) sdn Bhd

C&W Services Deploys Wireless Predictive Maintenance to Fix a Dated Walkaround Program

C&W Services implemented a wireless and AI-based predictive maintenance (PdM) solution from Petasense at a leading pharmaceutical and biotech client’s facility to automate data collection, improve asset reliability, reduce equipment downtime and achieve better resource allocation by continuous monitoring of critical machinery...

- Ken Madsen

- Petasense

Machine Monitoring and How ESA Technology Can Upgrade Your Plant’s Reliability

In many cases, the quality of the power supplied to the motor system may be the cause of a breakdown or failure. The result of poor “power quality” is usually long term and often overlooked as the source or contributor to the problem. Knowing the quality of the incoming power, along with the mechanical and electrical condition of motor and the mechanical condition of the drive are important at all facilities to maintain uptime & save money...

- Bill Kruger

- ALL-TEST Pro

Arizona Public Service Justifies Large-Scale Implementation of Wireless Predictive Maintenance

Southern California has a lot of solar generation, and APS wanted to use Sundance for rapid ramping in the shoulder hours (morning and evening) to add energy to the grid in hours when solar isn’t generating. They started looking for a wireless Predictive Maintenance (PdM) system...

- Ken Madsen

- Petasense

- 1

- 2

- 3

- 4