Articles

Smart Condition-Based Maintenance (CBM) – Do More than Identify Defects

More and more companies are proactively monitoring their assets using at least one technology to provide early defect identification. This makes up the core of condition monitoring – allowing you to identify and address defects early, before they compound and cause further damage, result in unplanned equipment downtime or compromise employee safety.

- Marcus Erickson

- Allied Reliability

How We Created a Software that Helps Facilities Manage Their Maintenance Operations

Jeff Roscher had a great interview with Nathan Grieve, from Project Hatch, that was released this morning. The article will take you through Jeff’s successful journey in the building of an award-winning computerized maintenance management system (CMMS)..

- Jeff Roscher

- eWorkOrders

How Motion Amplification® Fits into a Reliability Program

If you want the equipment and assets in your industrial facility to stay up and running, you’ll need a good reliability program. Reliability programs are designed to increase and maintain the performance of a plant’s equipment by identifying potential failures and eliminating their causes and reducing the possibility of production failures and stalls while enhancing safety.

- Jeff Hay

- RDI Technologies

Crossword: Asset Management

- Alynn Kayatta

- Mobius Institute

Complicated Versus Complexity in Maintenance

I’ve always thought that knowing when something was going to fail was unknowable. Of course, predictive maintenance vendors shout from the rooftops about the effectiveness of their technology. Even the onboard computers tell you to replace components, somehow knowing when the failure will occur.

But really, most failures are not related to wear or aging, so how can we know what is going to happen and when? This discussion leads me into the sales pitches for AI (Artificial Intelligence). Can we ever get to the point where there is so much data that we can really predict the future?

- Joel Levitt

- Springfield

The Relation Between Reactive, Run to Failure (RTF), and Corrective Maintenance (CM)

Failure-based Maintenance (FBM) is unscheduled maintenance or repair to return the asset to a defined state. There are no interventions until a failure has occurred. This includes the Reactive Maintenance and the Run to Failure (RTF) Maintenance. Many are not differentiating between the above-mentioned types of Maintenance and use the two terms as alternatives.

- Ahmed Kotb

- Self-employed

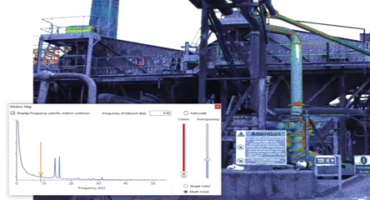

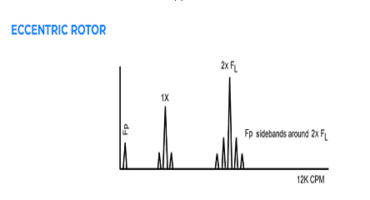

Electrical Frequencies Calculation and AC Motor Faults Patterns. Part 2

In the Part 2 the practical example will be analyzed.

Let’s look the background and calculate the most common frequencies produced by motor that potentially will be required for further analysis.

- Pawel Lecinski

- CMRP

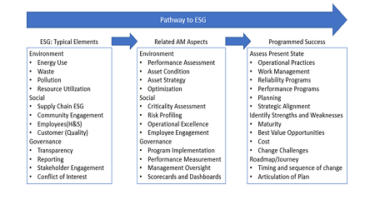

Asset Management Enabling Environment, Social, and Governance (ESG) Principles

At a high level, corporate social responsibility refers to practices and policies undertaken by corporations that are intended to have a positive influence on the world. Along these same lines, there is a growing desire in many organizations to practice environment, social, and governance (ESG) principles in their everyday business operations.

- Chris Colson

- Allied Reliability

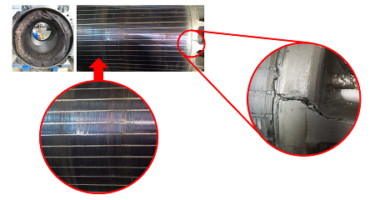

Electrical Frequencies Calculation and AC Motor Faults Patterns. Part 1

The fault diagnosis of induction motors, being probably the most common drivers used for industrial machinery plays an important role to reduce the catastrophic failures and production lost tonnage.

- Pawel Lecinski

- CMRP

- 1

- …

- 3

- 4

- 5

- 6

- 7

- 8