Articles

Checklist for Implementing an Electrical Preventative Maintenance Programme

Electrical equipment failures especially motors account for nearly half of facilities downtime, and the difference between a poor Electrical Preventative Maintenance programme and an excellent one is approximately 12 times.

- Mark Gurney

- 3Phi Reliability

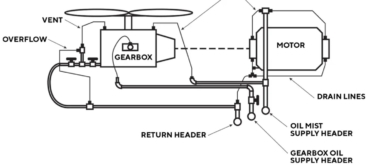

Extend Asset Life with Oil Mist for Storage Preservation

Balancing today’s lengthy lead times/supply chain issues with the need to keep critical operations running smoothly, petrochemical and refining plants are hedging their bets by proactively ordering new or replacement equipment (e.g., pumps and motors) a year or more in advance of the anticipated install date.

- Keith Macaluso

- T.F. Hudgins, an Allied Reliability brand

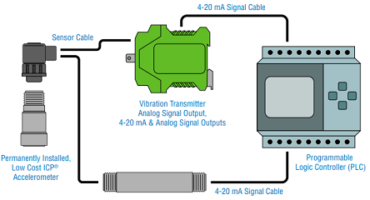

Monitoring the Pulse of Machine Health

So many machines, so little time! An overview of benefits and limitations of condition-based vibration analysis as a tool to optimize your PdM schedule. You’ll learn the capabilities of earthquake switches, electronic switches, programmable accelerometers and vibration transmitters. Plus, how to determine whether wireless vibration monitoring is a good fit for your facility.

- Bob Martin

- IMI Sensors

The First Step in AI Based Predictive Maintenance

With the increasing demand of IIoT in the age of digitalization, data-driven maintenance optimization of industrial equipment is one of the most trending topics among maintenance professionals. At the beginning, data gathered by various sensors placed on the machines or embedded in the machine itself are pre-processed.

- Anil Ulusoy

- Sensemore.io

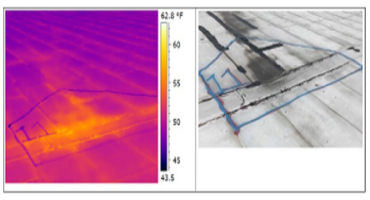

Check Sheets- Something is Missing, I Think…

Have you ever completed an infrared survey and wondered if you’ve missed something that should have been inspected? Do you know the special safety instructions to open certain electrical cabinets? Has management ever asked you when was the last time that you’ve inspected a specific cabinet and you couldn’t answer them? If you have answered yes to any of these questions, you need to develop a check sheet for the equipment that you inspect.

- Patricia Warner

- Cummins Inc.

Asset Strategies

Many organizations suffer higher costs and lower productivity than is possible. They react to equipment health problems. They don’t have good plans on how to best care for equipment. Without a good plan, or if unable to execute the plan, it is nearly impossible to get ahead of the maintenance cycle of doom, or to keep from falling back into it.

- Tom Moriarty

- Alidade MER, Inc.

Playing it Safe — How to Avoid Arc Flash Explosions

Working around electrical equipment, it’s imperative to understand the potential hazard of arc flashes, what causes them, and how to prevent serious damage to people and assets. When electrical current passes through the air from one point to another, the resulting arc flash can reach temperatures up to 35,000° F. An arc flash is the light, concussive energy, and heat produced as part of an arc fault, a type of electrical discharge that results from a connection from phase to phase, or phase to ground.

- Mike Levitt

- Allied Reliability

5 Ways Machine Learning Improves Asset Performance in Power Plants

A 500 MW power plant generates about 10,000 data points every second. It’s impossible for humans to review all this data and use it to optimize plant performance.

- Mohan Amasa

- AssetSense

Succession

I spoke to a group of maintenance professionals last week in the Caribbean (virtually), and the topic of succession came up. The group consisted of men and women at various points in their careers, but there was a strong contingent of senior leaders and a few newbies.

- Joel Levitt

- Springfield

- 1

- 2

- 3

- 4

- 5

- 6

- …

- 8