The need to align manufacturing maintenance processes between production and maintenance has been a long-standing challenge for manufacturers. Production and maintenance are focused on different yet overlapping areas of operations. Production directs their efforts to producing as much product as possible running at maximum capacity. Maintenance meanwhile needs to manage the equipment and machines to ensure production capacity is available.

A holistic view enables the better management of the asset lifecycles and the prevention of excessive unscheduled downtime. One of the main challenges comes from when the maintenance department does not receive enough information to know what the top priorities are. There is also the risk of maintenance not responding quickly enough to unscheduled downtime events. These incidents cost time and money – and reduced customer satisfaction when orders are delayed. This disconnect introduces inefficiencies across the internal and external supply chain.

But what if maintenance and production operations had a better way of working together?

Many factories have been implementing Industry 4.0 technologies for greater agility and efficiency in their facilities. This foundation enables access to a subset of that technology, Maintenance 4.0, that provides intelligent management of systems and equipment. The integrated insights lead to improved asset lifecycle management and more efficient workflows.

The Production vs. Maintenance Challenge

When assessing facility needs, production will often say that they need to maximize output which means minimizing maintenance-related downtime. A common view is that manufacturing maintenance takes too long or there isn’t enough communication between the departments. Downtime means loss of efficiency, reduced production and ultimately, lost revenue and profits.

On the other side, maintenance has concerns surrounding production operators being trained properly with equipment so that it is less likely to break down or be damaged by misuse. Being alerted slowly can affect the facility’s bottom line by halting production for a significant amount of time. There can be difficulty in communicating that production can resume once a repair has been made. Another challenge is scheduling the appropriate amount of time for upkeep, such as belt replacements or warranty work.

The challenge is breaking down these traditional silos, and integrating the data between the two departments, enhancing communication and increasing decision making, for the better of the company. Production operations have information from customer orders and their production machines. Maintenance receives work orders when equipment is are, or not functioning properly. This team is also responsible for scheduling regular upkeep and warranty work. When the data is shared and accessible, a synergy forms between the two teams that drive greater efficiencies, reducing production lead times and increasing the level of customer service.

An Integrated Example

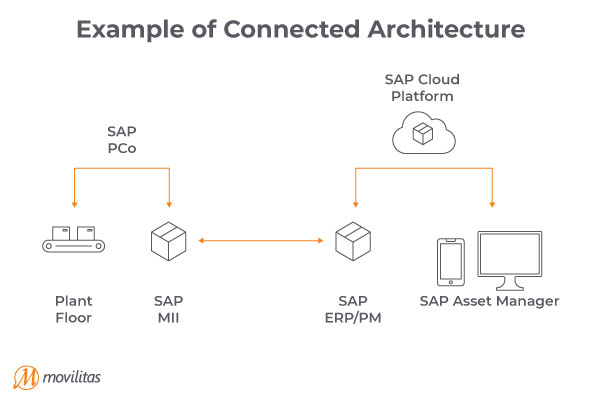

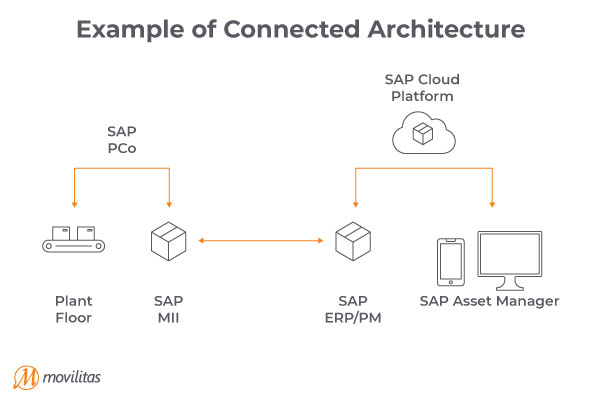

Here is one example of how you can capture critical information and share it with relevant parties. On the SAP MES side, there is either SAP Manufacturing Integration & Intelligence (MII), SAP Manufacturing Excellence (ME) or SAP Digital Manufacturing Cloud (DMC). On the maintenance side, there is SAP Asset Manager. Their systems can be connected via cloud software that also enables integration with your ERP. The image below provides this version of the connected architecture.

Once this integration is in place, the information can be applied to multiple situations. For instance, when a production line or machine is down, an alert is sent to both production operations and maintenance in real-time. A maintenance work order can be automatically generated. Maintenance will have the right details to determine what is needed, who is needed and what resources are needed. After the work is completed and everything is back online, a message is sent to production. This flow of information decreases downtime.

Over time the data can be used to see trends and help schedule the regular upkeep based on what the equipment needs. This step puts your operations on a path towards conditional and predictive maintenance, a Maintenance 4.0 key component.

The Benefits

The many advantages of a connected system enable you to:

- Reduce unscheduled downtime with faster responses and time to resolution

- Minimize unscheduled downtime events by scheduling maintenance more efficiently

- Increase overall OEE with better machine availability and performance

An integrated framework supports the improvement of production operations and manufacturing maintenance. The results are increased productivity, efficiency and profitability of your facilities.