Addressing Manufacturers’ Concerns Towards Data-Sharing

In today’s interview with Vatsan Govindarajan and Arnulf Hagen, we focused on learning about:

- How does SAP PEI fit into the larger ecosystem of enterprise asset management?

- How does Asset Central, a re-usable asset registry across IoT applications for seamless integration and data consistency, play a central role?

- What are the low-hanging fruits in a customer’s digitization journey?

- How does SAP address a manufacturer’s concerns towards data sharing and data security?

- What is SAP PEI’s product road map for Q4’18 and 2019?

SAP PEI’s integration with SAP Enterprise Asset Management (EAM)

Annabelle Roux: One of the main values of SAP PEI is its integration with the whole enterprise asset management ecosystem. How does it help customers?

Vatsan Govindarajan: The data models that we use in SAP PEI are integrated with SAP’s Asset Central. We are also integrating it with a predictive maintenance module where we combine these insights with the generic machine learning (ML)- and artificial intelligence (AI)-based models. We combine these two to deliver valuable insights.

The real value lies in integrating the aforementioned insights (based on SAP PEI data models and generic ML/AI data models) with the Asset Intelligence Network (AIN). We further integrate it with SAP’s enterprise suite.

By adopting this continuous integration strategy, SAP PEI does not remain a siloed system anymore; it can convert insights into action.

Our next-generation asset management portfolio consists of four key products. These include:

Asset Central

Annabelle Roux: The Asset Central is the main component of the digital core. Does it act as an asset register that consists of all the asset information shared amongst the different components?

Vatsan Govindarajan: Asset Central remains the central repository of all assets for a variety of applications. If you’re using Asset Intelligence Network and move on to Predictive Engineering Insights, you don’t have to redo the entire master data because everything is integrated with Asset Central.

Baseline Use Cases

Annabelle Roux: What are the low-hanging fruits that customers should aim for when they initially embark on their asset digitization journey?

Arnulf Hagen: The lowest-hanging fruit is to make sense out of the entire asset data that customers receive from multiple sources, and then implement simple alerts or trigger actions based on these alerts. Customers can even give their engineers the ability to work with these assets, and new instruments to understand the behavior of what is going on with the assets.

Users, customers, or any owner of an asset is faced with exponentially growing sets of signals from their assets. The assets are yelling all kinds of messages in different languages. It’s becoming a rapidly increasing problem to understand what to do with all these signals.

We run analytics on these signals and enable data owners to obtain actionable insights.

If a customer is faced with an inability to act, due to lack of data organization, we simplify it with this model-based approach. The approach may be used for simple alerting as well.

For instance, there was a recent incident where a motorway bridge collapsed in Genoa, Italy. Such events happen rarely but if they do, it’s a huge deal. It is possible to detect such events if it’s done in a proper way. Signals need to be transferred to an interface that humans can understand.

The New Normal

Vatsan Govindarajan: A lot of business-use cases have become a low-hanging fruit because the new technologies such as cloud computing, Big Data, and engineering simulation are converging. The convergence makes it easy for business users to obtain insights without investing a lot of time and resources.

It can be applied to almost any kind of asset category. And I do believe we can deliver tremendous value. Five to ten years from now, I would presume that people would not imagine having these sophisticated solutions to monitor assets. This will just become the new normal.

How to Set Up the SAP PEI Solution?

Annabelle Roux: How should the customer go about building the digital twin? How exactly are the relationships between SAP, Fedem, and ANSYS? Is SAP the single point of contact?

Vatsan Govindarajan: Customers have a single point of contact with SAP and we bring in our partners like Ansys as necessary to help deliver the most value from our product.

Addressing Manufacturers’ Concerns Towards Data-Sharing

Annabelle Roux: Do customers have to collaborate with the manufacturer of the asset?

Vatsan Govindarajan: The question has been raised a couple of times previously in different ways such as:

- Will the manufacturer share the designs?

- Will they share the model information?

Since it does not create an IP (intellectual property) issue, we have seen several cases where there has been no hesitation for a customer to approach their manufacturers.

Arnulf Hagen: It is a black box that prohibits reverse engineering of the product. At the same time, its main behavior is open to the user. From my perspective: it’s a win-win. I’ll elaborate.

There is a legitimate concern from manufacturers regarding the production or the concept of digital twins, because it implies that information about the product is transferred to another business entity, whether it is SAP who hosts the model or the customer who can manipulate it. Another concern is that the IP will leak, together with this data model.

Most of this data is related to geometric information, material properties, details in a control system, mechanisms, and how they work. And that is not necessarily needed in producing a digital twin.

In Fedem, this product may be reduced to a mathematical representation as no geometry is needed in the final runtime. In case of ANSYS, this system may be reduced runtime as a program or reduced to a model running like a program where all the IP-sensitive data is either left out or is embedded in code. From the perspective of customer or manufacturer, it is a watertight arrangement.

Data Acquisition and Data Security of Connected Systems

Annabelle Roux: Do you get most of the data for the modeling purpose directly from the customer and the manufacturer?

Arnulf Hagen: With modern assets built for industrial use, customers have a CAD model to start with and this CAD model is the origin of the digital twin, but it will then be manipulated so that only the relevant information is taken out. The relevant information may not be IP sensitive. In a new build, or in systems that come online, it will come from the manufacturer.

In case of old systems, we adopt a different strategy which involves engineering or representing the data using drawings and knowledge about the material properties. Going forward, the information will already reside some way or another with the manufacturer.

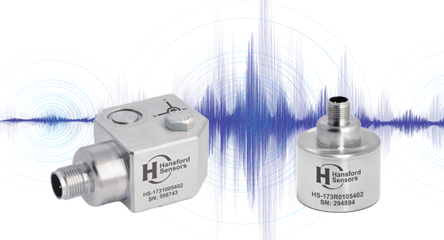

Annabelle Roux: Does all the data come from the sensors alone?

Arnulf Hagen: It’s an important question. Sensors are simply sources of information. There are other sources of information such as control systems that they already pick up signals from or have information about the operational condition. This will be used in the context of Predictive Engineering Insights.

There may be information from outside sources, such as the weather, satellite information or traffic information in order to understand the responses in bridges. Sensors are simply one main source to understand the physical behavior of an asset, but to make sense of it, one will gradually integrate more and more information from various sources and provide deeper insights.

The goal of Digital Twin was to go back to create the bridge between the physical and the digital world.

The deeper insights the Digital Twin has from the physical world, the more it is able to make sense out of it, and trigger actions based on these insights. There are definitely more sources and sensors and they will gradually come online. We’ve already started working on them.

Product Roadmap and SAP PEI’s Future Direction

Annabelle Roux: What are some of the planned innovations and product roadmap for SAP Predictive Engineering Insights?

Vatsan Govindarajan: In general, it must be noted that all plans on the product roadmap are subject to change. The focus going forward will be to strengthen our partnership with ANSYS. We plan to fully embed ANSYS runtime into the PEI stack.

We are also delivering new applications for vibration analysis, which is not completely focused on Digital Twin. It is related to physics-based analysis of vibration that includes the frequency domain.

The product development team has planned multiple feature additions. For instance, my colleague Arnulf is leading the use case of monitoring bridges. It is not yet a concrete part of the roadmap; however, it is in the validation stage. From a roadmap perspective, below are the main things planned for the November 2018 release:

- Vibration analyses with frequency inspections and spectrograms

- Embedding of the Digital Twin runtime

- IoT creation based on frequency spectrum envelopes

- Integration to the Asset Central, and the asset portfolio of SAP

In February 2019, we plan:

- To embed the next round of ANSYS Digital Twin deployment for condition monitoring

- Frequency domain failure mode analysis

- Enhanced integration with Asset Central with indicators and the integration of SAP IoT services for data injection